High temperature hydraulic oil of excavator can be solved in three minutes!

December 11, 2022

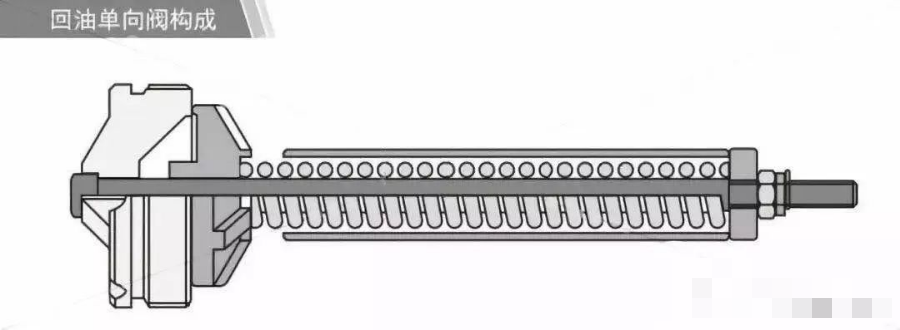

The high temperature of hydraulic oil has always been a headache for excavators. How to effectively solve the problem of high temperature of hydraulic oil, If the high temperature of the hydraulic oil is not handled in time, the internal leakage of the hydraulic pump, main control valve and various working devices will be achieved in the long run, and must be repaired or replaced in serious cases. Fault caused by return check valve The return check valve is mainly used to make the return oil generate enough pressure to compensate for possible cavities in the system, and prevent excessive return oil disturbance or impact from damaging the radiator and swing motor.

The oil return check valve is a device that the hydraulic oil returns to the hydraulic oil tank from the main control valve to the working device. There are two devices, one is installed between the main control valve and the hydraulic oil tank, and the other is installed between the main control valve and the hydraulic oil radiator. Because there are two oil return check valves, if the oil return check valve on one side of the hydraulic oil tank is damaged, leaks and is stuck in the normally open state, then the hydraulic oil directly enters the hydraulic oil tank, causing the high temperature of the hydraulic system. Similarly, if the oil return check valve on the radiator side is stuck, then the hydraulic oil directly returns to the hydraulic oil tank without passing through the radiator, causing the high temperature of the hydraulic oil. If the two return check valves are removed and not used, not only the high temperature of the hydraulic oil, but also the excessive pressure of the return oil will cause impact damage to the hydraulic oil radiator (that is, the return check valve at the side from the main control valve to the hydraulic oil radiator is damaged or not installed), but also the swing motor will be damaged due to the inability to replenish oil.

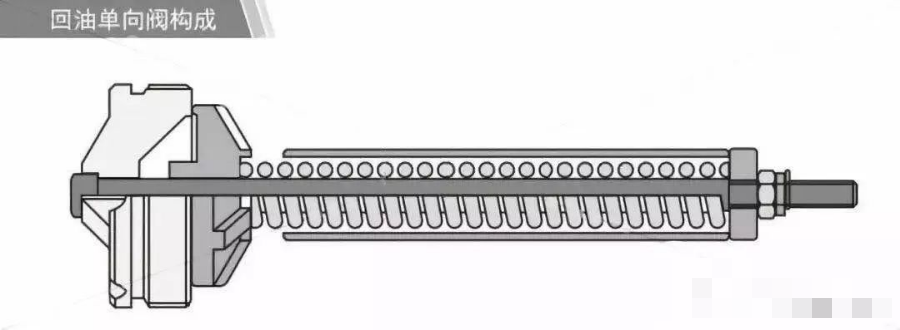

Troubleshooting It is determined that the high temperature fault is caused by wear, jamming and leakage of the return check valve. There is only one solution: replace the return check valve with a new one; When purchasing, you must purchase and install according to the standard pressure of the original factory, otherwise the pressure of the return check valve on the side of the oil tank is lower than that on the side of the radiator, and the hydraulic oil directly returns to the oil tank, which will also cause the hydraulic oil temperature to be too high. Note: (If the hydraulic oil is not replaced for a long time, the quality of the hydraulic oil is poor, and the impurities in the hydraulic oil are too much, the return check valve will be worn or damaged, and in serious cases, the hydraulic pump, main control valve and working device will also be damaged. Therefore, the hydraulic oil must be replaced on time during daily maintenance to prevent the wear of hydraulic components). Return check valve pressure The pressure of the two return check valves on the excavator is different. The pressure of the return check valve on the side of the distribution valve (main control valve) returning to the hydraulic oil tank is 0.5-0.3MPA.

The pressure of the return check valve from the distribution valve (main control valve) to the hydraulic oil radiator is 0.3-0.15MPA (different tonnage, different pressure). The two return check valves must not be installed reversely, or they will have no effect and will still be hot. How to avoid high temperature of hydraulic oil (1) Clean the radiator regularly. The working environment of construction machinery is poor and there is much dust. The dust and oil dirt adsorbed on the external surface of the radiator will seriously affect the heat dissipation effect of the radiator; The radiator shall be cleaned regularly to remove dirt and maintain good heat dissipation performance. (2) The hydraulic oil shall be selected reasonably. The hydraulic oil shall be selected according to the brand recommended by the manufacturer and the working environment and temperature of the machine; For some machines with special requirements, special hydraulic oil shall be used; In winter in the north, it is better to select low pour point hydraulic oil; When the maintenance of hydraulic components and systems is inconvenient, anti-wear hydraulic oil should be selected. (3) Adjust the system pressure according to the standard. The components used for pressure regulation are mainly relief valve and safety valve: in the constant displacement pump system, the oil supply pressure of the hydraulic pump is regulated by the relief valve; In the system of variable displacement pump, the safety valve is used to limit the maximum pressure of the system and prevent the system from overload; The pressure value of the control valve shall be adjusted strictly according to the standard to reduce the energy loss. (4) Prevent pipeline blockage and oil leakage. The oil inlet filter element and oil inlet pipe shall be inspected and maintained regularly to prevent the oil flow from being blocked due to pipe blockage; Tighten all connections of oil pipes in time, regularly check the oil seals of pilot pump and main hydraulic pump drive shaft, and replace the damaged oil seals in time. (5) Timely repair worn hydraulic components. The hydraulic pump and motor shall be checked regularly, and the hydraulic components with severe wear shall be overhauled in time. Of course, the excavator with too long service life and improper maintenance is prone to high temperature. In this case, not only check the return check valve, but also check the radiator, hydraulic pump and other components carefully. The high temperature fault of hydraulic oil is difficult to deal with and easy to recur, so we must be prepared for the daily construction and maintenance work!