How to choose preservatives in metal working fluids!

Common microorganisms in water-based cutting fluid are Escherichia coli, alcaligenes faecalis, Pseudomonas aeruginosa, Aspergillus nigricans, penicillium, candida albicans, etc. Once they prolifze in the cutting fluid circulation system, they will degrade organic components, consume emulsifiers, precipitate oil phases, and the concentration will decrease and the lubrication performance will also decrease. The pH value and anti-rust performance are decreased by microbial fermentation, and the reproduction of bacteria is further promoted. After sulfates and sulfonates in cutting fluid are decomposed by sulfate-reducing bacteria, hydrogen sulfide gas is produced, which has an unpleasant odor and has an adverse effect on the production environment. In severe cases, microorganisms can form microbial membranes on the wall of the pipeline, becoming stubborn pollution sources, and even blocking the pipeline. The health of on-site employees can also be damaged, such as skin allergies and wound infections.

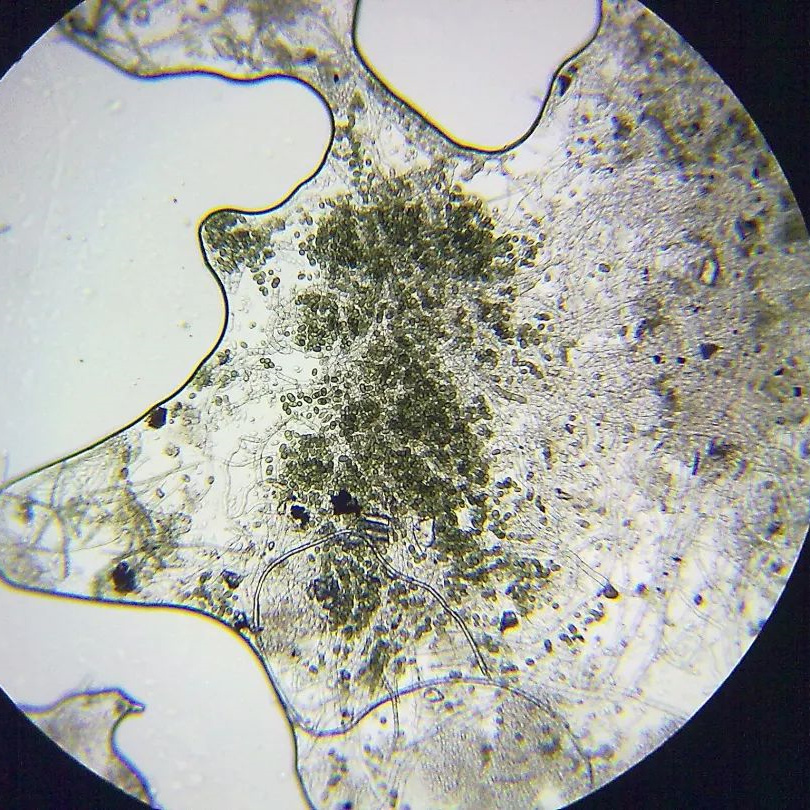

In order to eliminate the above mentioned hazards, corresponding measures must be taken to control the growth of microorganisms. When the bacteria number is between 102-104CFU/ml, there will be no problem in the operation of the cutting fluid system in most cases. But for mold, it's a different story. Mold does not distribute evenly throughout the coolant system, but instead forms colonies. This situation can often occur in the cutting fluid system. If mold is found in the cutting fluid system, it is necessary to pay special attention and take appropriate measures as soon as possible.

Commonly used chemical preservatives have the following three mechanisms of action: The first category includes compounds that can cause the loss of membrane permeability, which leads to the leakage of cell contents and the loss of the energy gradient coupled with the membrane (such as phenols); The second category includes compounds that inhibit or inactivate intracellular enzymes, which are often combined with sulfhydryl reactions at the active site of the enzyme to affect the activity of the enzyme (such as aldehydes, formaldehyde derivatives); The third category includes the destruction of genetic material. These compounds prevent the cell from replicating, and even affect the synthesis of substances and the cell's respiration. Isothiazolinones not only damage the basic enzymes, but also affect the permeability of cell membrane and the synthesis of nucleic acid, so they have three kinds of mechanisms at the same time.

Taking into account the characteristics of water-based metal cutting fluids, the chemical preservatives applied in them should meet the following requirements:

(1) The efficacy of a broad spectrum of microorganisms, at the recommended concentration can effectively kill bacteria, molds and yeasts.

(2) Rapid sterilization.

(3) Long-term performance.

(4) Good compatibility with the ingredients in the processing fluid.

(5) Good thermal stability.

(6) Good material compatibility, such as does not rust the workpiece, does not destroy the sealing material.

(7) does not affect the cooling and lubrication performance of the processing fluid.

(8) Little effect on the pH value of the processing fluid system.

(9) has no negative impact on the environment, such as low odor, does not cause skin allergy, low toxicity and biodegradable.

(10) Reasonable cost.

No single anti-corrosion active ingredient has been found to meet the requirements listed above. Therefore, preservative manufacturers can better meet the actual corrosion protection needs of metal processing by artificially optimizing the combination of different active ingredients. The following introduces some active ingredients commonly used in metal working fluids to prevent corrosion.

1. Aldehydes

Among the aldehydes, formaldehyde, glutaraldehyde, benzaldehyde and chloral are known. Among them, 30% to 40% formaldehyde aqueous solution is the simplest form, which has a good anti-corrosion effect. However, formaldehyde only has a strong killing effect on bacteria, and its effect on mold is weak. Due to the irritating smell of formaldehyde, few people use pure formaldehyde as a preservative, and the application of glutaraldehyde has been paid more and more attention.

2, formaldehyde biological

There are two forms of formaldehyde releasers: 0-formaldehyde and N-formaldehyde. 0-acetal is produced by the reaction of primary alcohol, ethylene glycol or ethylene glycol ether with formaldehyde. Common ones are benzyl alcohol, propylene glycol and 1, 2-ethylenediol. They are not as volatile as free formaldehyde, so they have better long-term performance and are particularly suitable for neutral processing liquid systems. 0-formaldehyde is a highly effective bactericidal component, which is produced by the reaction of formaldehyde with amines or amino compounds. Common are hexahydrotriazines, imidazoline, oxazolidines, acetal amines, and hydroxymethylamide compounds.

3. Thiazoles/isothiazolinones

Inhibition of bacteria and mold [e.g., 2-mercaptothiazoline or 2-(4-thiazolyl) -phenylimidazole]. People have been trying to use them: for the corrosion protection of processing fluids. However, their application is restricted by solubility, stability and cost.

Phenylpropyl isothiazolinone and other isothiazolinone derivatives have also been used as preservatives for several years. However, the composition and structure of the processing fluid will directly affect their efficacy. Due to the low solubility, the application of phenylpropyl isothiazolinone is limited. The presence of nitrogen, amines, mercaptans and sulfites greatly affects the efficacy of the combination of chloromethyl isothiazolinone and methyl isothiazolinone. The combination of chloromethyl isothiazolinone and methyl isothiazolinone is highly toxic and corrosive to skin and mucous membrane when the concentration is high. So be very careful when doing this.

4. Phenols

In general, phenols play only a minor role in the corrosion prevention of processing fluids. Like other active ingredients, phenols have their advantages and disadvantages. The advantage is that the speed of killing bacteria and mold is fast. However, when the pH value is >9, the processing solution containing phenols is easy to cause skin allergy, and the presence of non-ionic emulsifiers will lose the bactericidal ability of phenols. For ecological and toxicity reasons, polyhalogenated phenols such as trichloro, tetrachloro or pentachlorophenol have been eliminated.

5. Cationic compounds

In terms of bactericidal efficacy, cationic active compounds can also be selected. However, due to its inability to kill common pseudomonas in water and incompatibility with anionic emulsifiers, its application is limited.

6. 3-iodo-2-propylene-butyl carbamate

3-iodo-2-propargyl-butyl carbamate has been used more and more as an anti-mold agent in processing fluids. It can be used in both concentrates and diluents of processing fluids, but stability issues should be considered when used in concentrates.

7. Amines

Recent research results show that amines can provide good rust protection and assist in sterilization, and can maintain good activity in anionic systems. However, in Germany, according to TRGS 611(German Technical Specification for Toxic Substances), imines are prohibited in processing fluids because they form nitrosamines in the presence of nitrating agents.

It is not simple to add various active ingredients to the cutting fluid to achieve a good anti-corrosion effect. Due to the many factors involved, and the diversity of bacteria, the difference of cutting fluid system and other reasons, higher requirements are put forward for anti-corrosion, and the selection of appropriate preservatives is the key.