Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

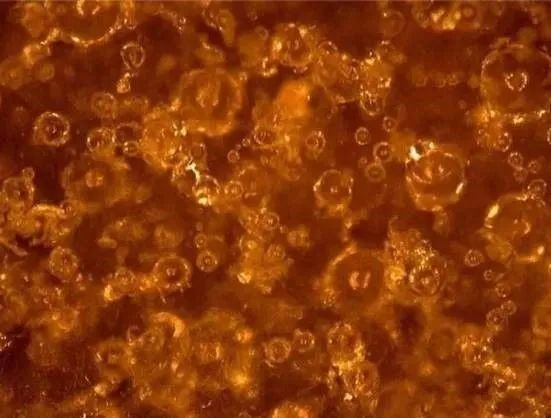

When the hydraulic system is working, the foam produced by hydraulic oil products seriously affects the dynamics of the hydraulic system, and may cause changes in bulk modulus, resulting in a series of problems such as cavitation, noise, oil degradation, oil temperature rise, oil quality degradation, etc.

Air mixed with oil products is the main reason for oil products to produce foam. In actual work, air may mix into the oil in various ways. For example, the connection part of the pipeline is not tight enough, the suction pipeline of the pump or the pipe seal has leakage, the oil inlet of the oil tank is high, and the oil in the oil tank is reduced, which will cause more foam when air enters the oil.

November 08, 2024

April 26, 2024

April 26, 2024

Discussion on the problem of difficult cleaning of drawing oil for cold rolled sheet In the process of cold-rolled sheet processing, stamping and drawing is an important link, and the use of drawing...

Problems and solutions of burr, corrosion, difficult cleaning, volatilization insecurity in the use of stainless steel stamping and drawing oil In the process of stamping and drawing of stainless...

Semi-synthetic water-based cutting fluid smelly foam rust discoloration and other 8 problems As an indispensable auxiliary material in modern metal processing, semi-synthetic water-based cutting...

What are the hazards of too high oil ash? The harm of excessively high oil ash and the importance of low ash oil In the modern automobile industry, with the increasingly strict environmental...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.