Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

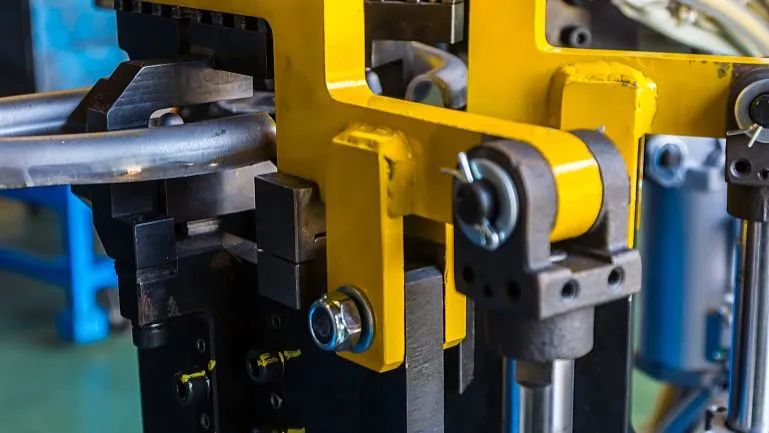

The viscosity grades of commonly used anti-wear hydraulic oil are 32 #, 46 # and 68 #. L-HN anti-wear hydraulic oil is suitable for low, medium and high pressure hydraulic systems of hydraulic equipment such as engineering, construction, mining and plastic processing, especially for high speed, high pressure and imported equipment hydraulic systems with requirements for oil cleanliness. It can also be used for lubrication of other low and medium load gear rotating devices, bearings and other industrial machinery.

The ashless antiwear hydraulic oil is applicable to the hydraulic system of metallurgy, engineering, mining machinery, marine auxiliary machinery and other fields or industries. Such as: the hydraulic system of furnace top machinery, forging, die-casting, steel rolling, extrusion, rolling, coiling and other machinery. Hydraulic systems for lifting, loading, excavating, shoveling, compactors, concrete, rock drilling and pavement machinery. Hydraulic system for lifting, crushing, perforating, mineral processing and special mine hoisting equipment.

First of all, antiwear Hydraulic Oil Additive system is divided into ashy (zinc) formula and ashless formula.

First, the ashy type is: zinc containing main agent, ZDDP, zinc dialkyl dithiophosphate, whose standard is 0.03% zinc content in oil.

Second, the ashless type is: zinc free. The advantage of ashless type is that it does not contain zinc element and will not react with parts with silver.

November 08, 2024

April 26, 2024

April 26, 2024

Discussion on the problem of difficult cleaning of drawing oil for cold rolled sheet In the process of cold-rolled sheet processing, stamping and drawing is an important link, and the use of drawing...

Problems and solutions of burr, corrosion, difficult cleaning, volatilization insecurity in the use of stainless steel stamping and drawing oil In the process of stamping and drawing of stainless...

What are the hazards of too high oil ash? The harm of excessively high oil ash and the importance of low ash oil In the modern automobile industry, with the increasingly strict environmental...

How to distinguish lubricating oil impurities from sediment? And different handling strategies In the daily management of lubricating oil, it is important to distinguish and effectively deal with...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.