Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: M1025

Brand: Chorus

Classification: Alkyne &Amp; Derivatives

Place Of Origin: China

Grade: Industrial Grade

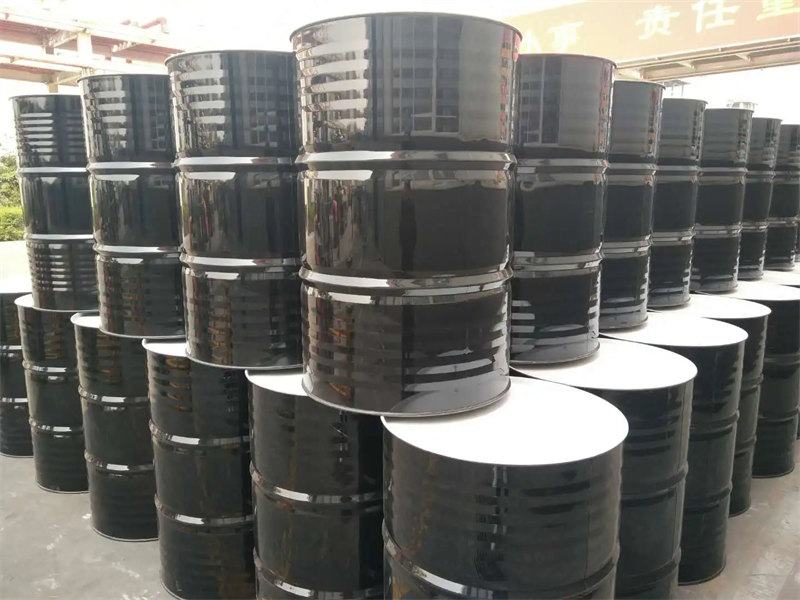

Package: Drum/IBC-Tank

Capacity: 10000MT/Year

Antifoam Performance, Ml/10min: 2

PH Value: 7.5-9.5

Surface Tension, MN/m: 40

Appearance: Amber transparent liquid

Packaging: 200L Iron Drums or 1000L IBC-Tanks

Productivity: 10000MT/year

Transportation: Ocean,Air,Land

Place of Origin: China

Supply Ability: 10000MT/year

Certificate: ISO

HS Code: 3811

Port: Shanghai,Qingdao,Tianjin

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,CIP

Introduction

Metal Working Fluid Concentrate M1025 is Ionic cutting and grinding fluid formulated from water-soluble rust inhibitor, lubricant additive, ionic surfactants, etc.

Features

Convenient to use, it can significantly improve the surface smoothness of the workpiece, reduce grinding wheel wear, improve grinding efficiency, extend the service life, and reduce environmental pollution.

Application

This product is a grinding fluid for high-precision grinding machines, and is also suitable for grinding ordinary grinding machines and centerless grinding machines.

Use Method

1. Dilute with ordinary tap water to a concentration of 3-5% during grinding, and it can be used. When cutting, the concentration should be set at 10-15%.

2. When using, it is necessary to regularly observe the pH value and effective component concentration, and regularly supplement the newly prepared working solution. If there is any deterioration or odor, it should be thoroughly replaced.

Product Typical Data

| Item | Index | |

| Appearance | Amber transparent liquid | |

| Antifoam Performance, ml/10min | 2 | |

| Surface Tension, mN/m | 40 | |

| pH Value | 7.5-9.5 | |

| Rust Resistance, 35 ± 2 ℃ | Cast iron single piece, 24h | Qualified |

| Lamination, 4h | ||

| Corrosion Test, 55 ± 2 ℃ | Cast iron sheet, 24h | Qualified |

| H62 Copper, 4h | ||

| LY12 Aluminium, 4h | ||

Package & Storage:

200L standard drum, 1000KGS IBC-Tank or made to order.

Store indoors above 0℃, out of direct sunlight, prevent water and other impurities from mixing in.

Product Categories : Metal Working Fluid And Additive > Water Soluble Fully Synthetic Cutting Fluid

Who We Are:

Zhengzhou Chorus Lubricant Additive Co., Ltd is a professional Lubricant Additive manufacturer integrating R&D, production, sales and service, with more than 10 years of experience. We are focusing on various Lubricant Additive Component & Additive Package, as well as Metal Working Fluid, component include Pour Point Depressant, Viscosity Index Improver, Antiwear/EP Additive, Antioxidant, Rust Preventative, Detergent, Ashless Dispersant, etc., Additive Package products widely cover the Vehicles & Industrial applications for PCMO, HDEO, 4T/2T Motor, Hydraulic, Gear, etc. In Addition, we have a lot of data to support (physical & chemical, simulation test, more than 80million kms field test). These approved reliable additives can ensure the production of high quality finished lubricant.

The products are exported to nearly 40 countries and regions in the world, also enjoy a good reputation in the international market with the satisfied service and high-quality products. "Sincerity, Innovation, Environmental Protection, Value" is our philosophy. We hope to create value for our customers through our high quality products and professional service. We are not just supplier but also partner to build up a brighter future for both parties, and make our world more clean and beautiful.

Our Factory:

We have a standardized production workshop of nearly 8000 square meters, 6 production lines. There are more than 60 workers, 15 salesmen, 20 technical engineers and 4 after-sales service team to make us able to provide good products and service. We have a complete factory production, quality control and delivery process, as well as a complete after-sales service system. All our products are provided with quality warranty and lifetime free after-sales service.

Packing & Delivery:

1. Package: 200L iron drums, 1000L IBC-Tanks, ISO-Tanks, pallets or made to order.

2. FCL load: It can load 80drums or 20IBC-Tanks per 20feet container.

3. Delivery: within 3-7days if there is stock, normal delivery time upon order is within 15days upon FCL order.

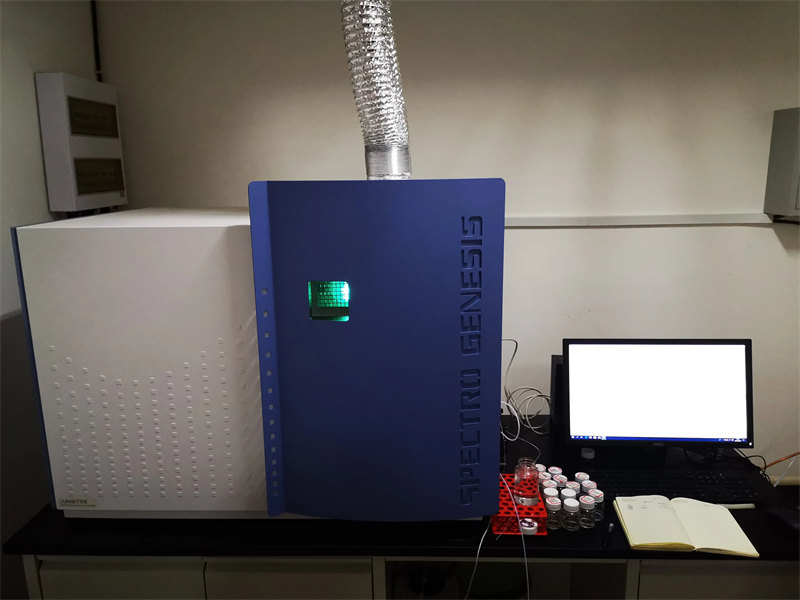

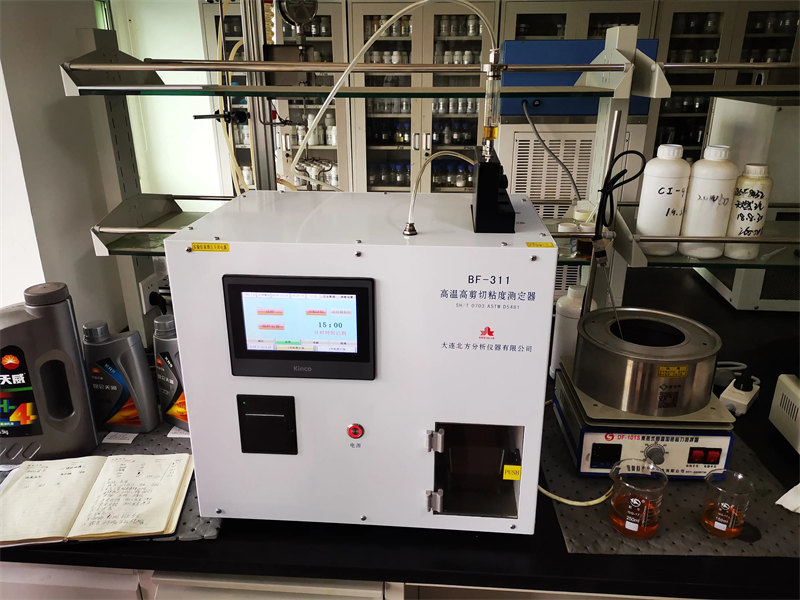

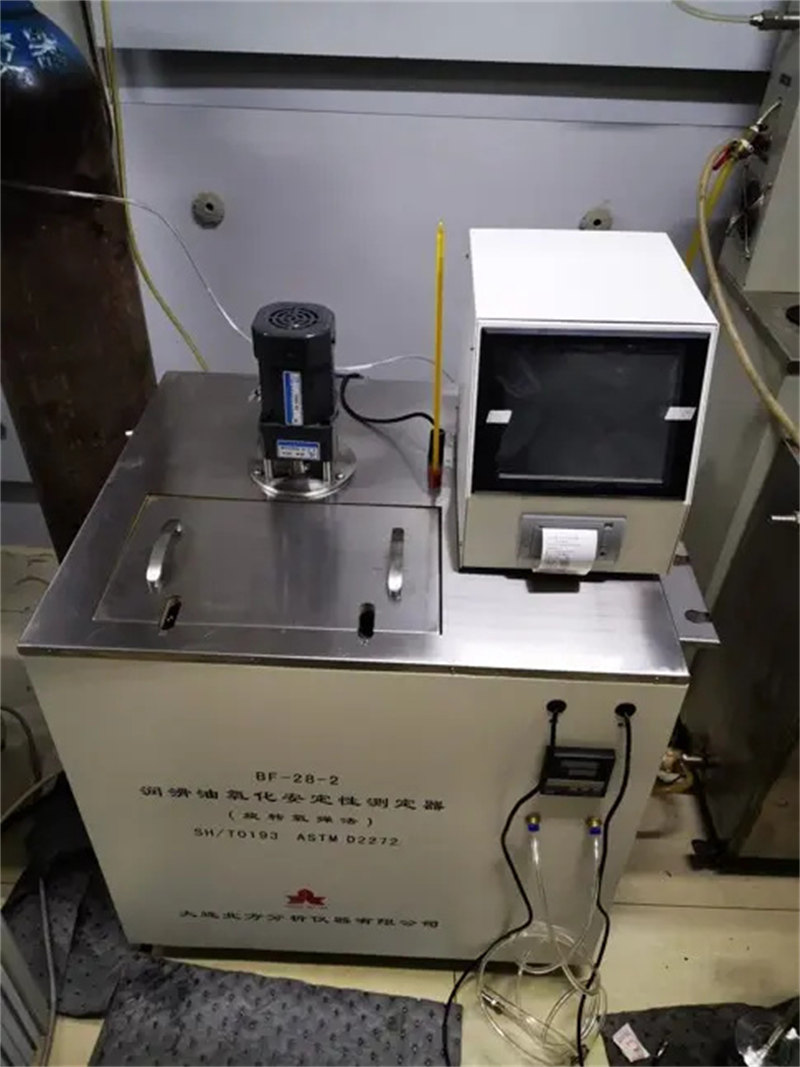

Some Important Test Instruments:

ICP Emission Spectrum Element Tester (imported)

High Temperature High Shear (HTHS) Viscosity Test Device

Engine Oil CCS Viscosity Tester

Four Ball Extreme Pressure Friction Tester

Lubricant Oxidation Stability Tester (RPVOT)

Copper Strip Corrosion Tester

Home > Products > Metal Working Fluid And Additive > Water Soluble Fully Synthetic Cutting Fluid > Metalworking Cutting Grinding Fluid Concentrate

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:8613783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.