Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The oxidation of lubricating oil is the reaction of lubricating oil molecules and oxygen molecules, which will lead to an increase in viscosity and the production of sediments such as sludge, additives will be depleted, and the Base Oil will also be decomposed. Once the lubricating oil starts to oxidize, its acid value will begin to rise. The presence of acid will cause the beginning of equipment corrosion.

Temperature is a factor that needs to be paid attention to during the use of lubricating oil. No matter what kind of system, the lubricating oil will be affected by the operation of the equipment (friction, kinetic energy conversion, heat transfer) and increase the temperature. Once its temperature exceeds the temperature at which the oil can maintain a stable temperature, thermal cracking will occur and intensify.

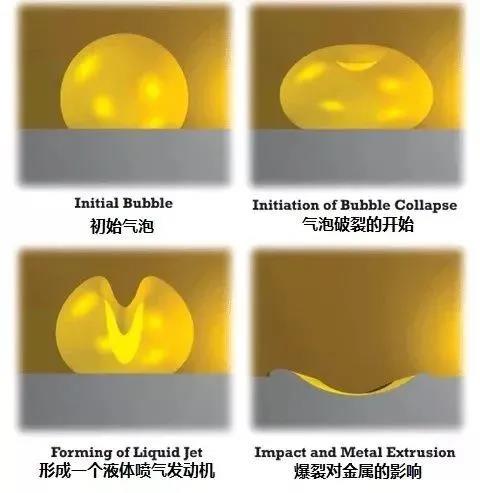

When the tiny bubbles in the lubricating oil enter the high-pressure area from the low-pressure area, it will cause a micro-deflagration phenomenon, or cavitation, due to pressure changes. Microscopic deflagration will cause the oil around the small bubbles to be instantly heated and oxidized. The temperature of the bubble burst area can reach 1093 degrees Celsius (2000 degrees Fahrenheit). Violent micro-deflagration can make the equipment emit obvious noise and vibration.

What harm will the deterioration of equipment lubricating oil cause to equipment?

Continuing to use the deteriorated lubricating oil will undoubtedly be detrimental to the lubrication protection of the equipment. We have summarized the following 8 hazards:

1. The acidic substances generated by the oxidation and deterioration of the oil will corrode the metal contact surface;

2. Additives in the oil will be gradually consumed, resulting in a decrease in the thickness and strength of the lubricating oil film and increased mechanical wear;

3. Decreased oil lubrication, cooling and flow properties will accelerate metal surface fatigue;

4. Oil sludge will block the filter system, and related parts need to be cleaned or replaced;

5. Oil sludge will greatly shorten the service life of sealing and guiding materials;

6. Oxidized and dirty oil will affect the action of the valve, causing the valve to jam and the valve core to wear quickly;

7. The system response becomes slower and accompanied by irregular actions, and the pressure transmission performance of the hydraulic system is reduced;

Through the above analysis, we should know that the anti-oxidation performance, the use of non-zinc anti-wear additives, and the excellent air release performance of lubricants will definitely have better performance and anti-deterioration ability, and will naturally be able to work under the same environment and use conditions. Get better performance and achieve longer service life.

The lubricating oil system of many large power plants and steel smelting enterprises will be carefully cleaned before the first oil filling. Special flushing oil is used to clean the dust and other foreign objects that may exist in the equipment system; before adding new lubricating oil, the oil The product (new oil, conventional cleanliness level 7-9) is filtered to reach a higher level of cleanliness (such as level 5-6) and then injected into the system.

First of all, it is necessary to avoid the deterioration of the purchased lubricating oil during the storage process. For example, storage in the open air, in the sun and rain, and the storage area is wet or close to the heat source, which will affect the quality of the oil.

Through the analysis of the oil samples of the oil in use, the data of its viscosity, acid value, water content, cleanliness, metal particles and other indicators can be obtained, and the operating conditions of the equipment and the lubricating oil can be analyzed by comparing with the corresponding indicators of the new oil. The degree of degradation.

November 08, 2024

April 26, 2024

April 26, 2024

How to distinguish lubricating oil impurities from sediment? And different handling strategies In the daily management of lubricating oil, it is important to distinguish and effectively deal with...

Optimization strategy of lubricating oil replacement cycle for gearbox of EMU In the daily operation and maintenance of EMU, the replacement cycle of gearbox oil is directly related to the operating...

In the season of Major Heat, protect the health of the engine - guard against the deterioration of lubricating oil Major Heat, the last solar term of summer, marks the hottest phase of the year. In...

Lubricating oil emulsifier characteristics and application of formula technology is excellent Lubricating oil emulsifier, as an indispensable chemical additive in modern industry, its application in...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.