Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

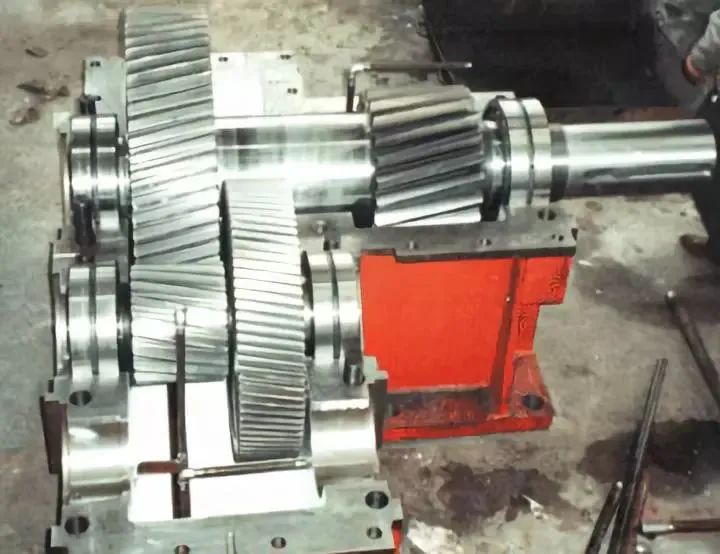

In order to improve the health of the equipment, the causes of the foam of the gearbox lubricating oil were analyzed, and several preventive measures should be taken in the daily regular inspection and operation maintenance were proposed.

The design of oil tank is unreasonable, the oil quality of oil pollution drops and enters the air - during the operation cycle of mechanical equipment, air is brought into the middle surface of oil to produce foam. Entering the air is a small amount of air distributed in tiny bubbles throughout the entire fuel tank.

The treatment of entering air is different from that of foam, which is usually a problem of complete separation. It is more serious than foam, and will cause pump cavitation, oil oxidation, etc. The air entering is different from dissolved air. Usually, oil contains 8-12% dissolved air in various oils such as industrial Gear Oil, engine lubricating oil, hydraulic oil, and guide rail oil, which contain additives with different properties. Most of these additives are polar compounds with surface activity, promoting the formation of bubbles in the oil.

During the use of lubricating oil, gum, asphaltene, and sludge residues generated due to oxidation and decomposition can promote increased foaming. Due to the aging and deterioration of oil products during use, the surface tension of oil products will decrease, which will also promote the production of foam.

How to prevent lubricating oil from producing foam

Anti foaming methods: physical mechanical anti foaming and chemical anti foaming.

Characteristics of anti foaming substances: (1) Anti foaming agents cannot be dissolved in lubricating oil; (2) Anti foaming agent can be evenly dispersed in lubricating oil; (3) The surface tension of anti foaming agents is smaller than that of lubricating oil.

1) Physical mechanical anti foaming

(1) Eliminate impurities.

Dust and coal powder are the culprits for the uncontrollable lubricating oil bubbles in the lubrication gearbox of the coal mill. Not only the dust itself, but calcium also adsorbs anti foaming agents. Check the filter and respirator for particles. Install filters in dusty areas. The exhaust port should be downward to avoid dust collection, especially in dusty conditions. Remove or reduce the substances that cause the lubricating oil to produce foam. Before loading or changing the oil, the entire lubrication system should be carefully cleaned, especially to remove the residue of the metal cleaning agent used for cleaning.

(2) Control the amount of air entering the fuel tank.

Avoid a large amount of air entering the fuel tank. The incoming air is released into the fuel tank, and the gears in the system will rotate and compress to produce bubbles. If the ventilation of the fuel tank is poor, the bubbles generated by gear agitation cannot be eliminated.

On the contrary, if there is pressure in the fuel tank, when the fluid enters the tank, the pressure is released, and a certain positive pressure on the surface will prevent the release of dissolved air. Firstly, eliminate the entry into the air source. If it is impossible or if there are too many bubbles that cannot be released, try to allow the fluid to flow along the slope and have enough time to be exposed to the air. Ensure that the fuel tank is grounded, or expand the tank area, or replace it with synthetic oil.

(3) The oil level is too high or too low.

The correct oil level is crucial. If the oil level is high, moving parts will bring in air. A low oil level will bring bubbles to the liquid level. The measure to be taken is to regularly observe the oil level gauge to ensure the oil level and prevent rapid temperature changes. In rolling bearings, the general rule is that the oil level is half of the bottom bead or roller. Too high is prone to blistering.

(4) Tank design maintenance.

Pay attention to the impact of fuel tank design on anti foaming performance, and filter blockage is one of the reasons for entering air. If there is no obvious pollution, bubbles will block the filter and it will disappear when removed. Note that diatomaceous earth filter elements can also cause air to enter. The measures to be taken are to ensure the correct installation of the filter, regularly inspect the filter or respirator for damage, blockage, and insufficient filtration, and carry out regular cleaning and replacement. Change the suction port downward to reduce particle entry. Basically, it ensures that the bubbles have sufficient time on the surface area to facilitate release.

(5) Oil temperature changes.

The environment and equipment operation mode are the main reasons for the rapid changes in lubricating oil temperature. The system can add cooling device according to the actual situation to control the oil temperature, so as to prevent the oil quality from dropping due to sharp temperature changes and foam generation.

2) Chemical anti foaming - adding anti foaming additives.

Shake the plugged cylinder vigorously to see if the foam or air can disappear within half an hour. If not, take samples to see if there is pollution, especially silicon, soap and cleaning agent. The sources of silicon include excessive addition of anti foaming agents, silicone containing and degraded silicone seals, as well as joints coated with silicone seals. Particles and grease will form stable foam. Anti foaming agents may lose their effectiveness in the presence of cleaning agents. Some anti foaming agents will adsorb onto exposed metal surfaces and separate from the oil.

Measures to be taken: Eliminate silicon pollution. Check for possible contamination of grease or seals and analyze for cleaning agent contamination. Eliminate the source of pollution, then empty, clean, add again, and thoroughly flush the joint. For the convenience of installing parts, silicone oil or heavy oil can be applied to the surface without using grease.

Check for leakage at the suction end of the high-pressure pump. Check the liquid flow design of the fuel tank, which causes repeated circulation of bubbles or insufficient time for separation, and handle it accordingly according to this suggestion. Changing the viscosity of the oil or using synthetic oil may be helpful. If the problem comes from the consumption of anti foaming agents, it should be confirmed first that there are no other reasons. Carefully add anti foaming agents.

It can be seen from the above reasons for the foam of lubricating oil that in daily work, measures such as adjusting the volume of oil tank to maintain a reasonable oil level, doing a good job in regular inspection, dredging the respirator, controlling the air intake in the oil tank, eliminating the pressure of foam release, strengthening filtration to remove impurities in the oil, improving the quality of lubricating oil, etc., combined with chemical Anti Foam methods, adding an appropriate amount of anti foam agent can effectively avoid and eliminate the foam of gearbox lubricating oil, And replacing lubricating oil, etc.

November 08, 2024

April 26, 2024

April 26, 2024

Discussion on the problem of difficult cleaning of drawing oil for cold rolled sheet In the process of cold-rolled sheet processing, stamping and drawing is an important link, and the use of drawing...

Problems and solutions of burr, corrosion, difficult cleaning, volatilization insecurity in the use of stainless steel stamping and drawing oil In the process of stamping and drawing of stainless...

Semi-synthetic water-based cutting fluid smelly foam rust discoloration and other 8 problems As an indispensable auxiliary material in modern metal processing, semi-synthetic water-based cutting...

What are the hazards of too high oil ash? The harm of excessively high oil ash and the importance of low ash oil In the modern automobile industry, with the increasingly strict environmental...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.