Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The quality of degreasing mainly depends on four factors: degreasing temperature, degreasing time, mechanical action, and degreasing additive.

In degreasing, the use of mechanical actions such as pressure spraying or stirring is very effective, because during spraying, fresh degreasing solution is forced to have good contact with the surface of the part, and the content of the entire degreasing solution is uniform, which is conducive to improving the degreasing effect; During spraying, mechanical force is used to promote the penetration of degreasing agent and damage the oil film, effectively forcing oil stains to detach from the surface of the parts; When spraying, it promotes the emulsification and dispersion of oil stains separated from the parts in the degreasing solution, preventing oil stains from adsorbing onto the cleaned surface of the parts. Mechanical action is particularly important in medium to low temperature degreasing. Generally speaking, pressure spraying is more than twice as fast as impregnation degreasing. The injection pressure is usually (0.1~0.2) Mpa (the degreasing agent used for pressure injection must be low foam to avoid excessive foam affecting normal operation and the loss of degreasing liquid), and the degreasing by impregnation cannot be considered as static impregnation. A circulating pump must be equipped to keep the solution stirring, and the circulating amount per hour is about 5 times of the tank liquid volume.

4. The effect of degreasing additives on the degreasing effect

The composition and usage of degreasing agents have a significant impact on the degreasing effect. For example, the degreasing effect of alkaline solution containing surfactants is better than that of alkaline solution alone. For solid or semi solid fats with high drop points, solvent cleaning is more effective than other degreasing methods. In order to improve the emulsification and dispersion ability of oil stains, it is effective to appropriately increase the content of surfactants in the degreasing agent. Different types of surfactants and different alkaline substances can cause certain differences in the degreasing effect. Good degreasing agents are determined through extensive experiments and repeated screening of their component matching ratios. For alkaline degreasing agents containing surfactants, the most effective cleaning effect is at the upper limit of the critical micelle concentration of the surfactant. During use, the degreaser will continue to be consumed, causing a decrease in concentration. Therefore, it is necessary to regularly supplement the degreaser to maintain the necessary concentration. The degreasing effect of a degreasing agent is not linearly related to its concentration. Therefore, for situations with high quality requirements for degreasing, a significant increase in concentration should not be adopted, but a secondary degreasing method should be used. The two degreasing solutions can be the same and there is no need to increase the concentration additionally.

November 08, 2024

April 26, 2024

April 26, 2024

What are the metal processing oils involved in wind power gear machining? As an important clean energy, wind energy will assume the major responsibility of the main force of new energy, it can be...

In the pipeline system of automobile exhaust pipes, the elbow is the weakest part, and its forming quality directly affects the performance of the entire pipeline. The plastic bending forming of...

With the upgrading of textile fabrics, the level of post-processing technology is required to be further improved, and the working conditions are more demanding. Therefore, in the oil lubricated...

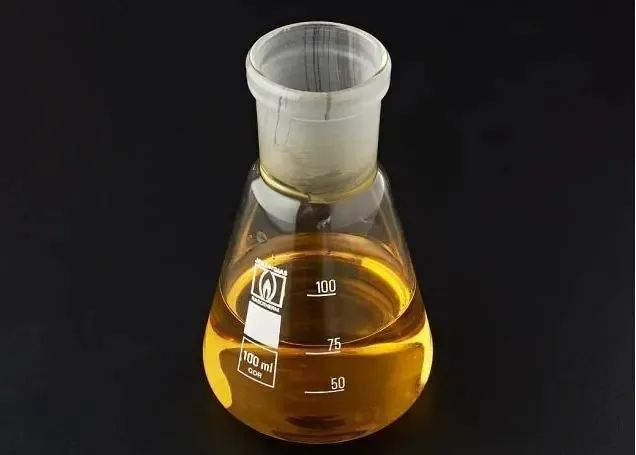

1. What is fire-resistant oil Fire resistant oil (EH oil) is composed of phosphate esters, with a transparent and uniform appearance. The new oil is slightly light yellow, without sediment, has low...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.