How harmful is the waste cutting fluid of machining? What is the best way to deal with it?

January 12, 2024

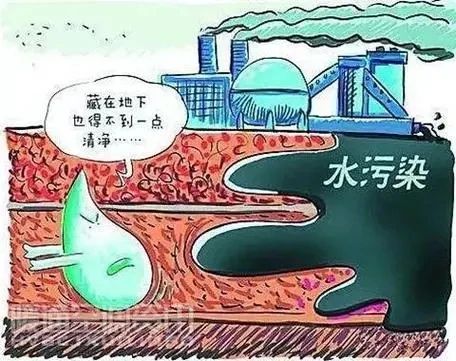

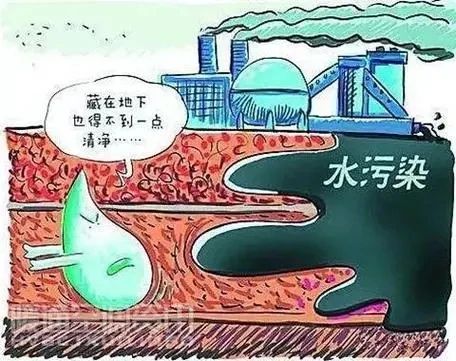

How harmful is the waste cutting fluid of machining? What is the best way to deal with it? As we all know, the cutting fluid widely used in the machining process has certain toxic side effects on the environment and the human body. It is an important subject of modern cutting fluid treatment to study and popularize the new technology of waste cutting fluid treatment. With the rapid development of modern machinery manufacturing industry, cutting fluid has been widely used in machining, and the amount has increased rapidly. However, because cutting fluid can cause pollution and damage to the environment and human body, the use of cutting fluid and waste liquid treatment have been increasingly restricted by environmental regulations. It has become an important subject of modern cutting fluid research to study and popularize the new technology of waste cutting fluid treatment. 01 Cutting fluid to the environment and human harm The harm of cutting fluid to the environment is mainly reflected in the pollution of its waste liquid to water resources and soil. Waste cutting fluid usually contains mineral oil, animal and plant oils, surfactants, extreme pressure additives, anti-fungal fungicides, various metal ions and suspended solids. Mineral oil is one of the main components of cutting fluid, its biodegradability is poor, can stay in water and soil for a long time, and its pollution of groundwater can be up to 100 years. The U.S. Environmental Protection Agency (EPA) states that mineral oil has acute lethal toxicity to aquatic organisms, as well as long-term subacute lethal toxicity. The concentration of mineral oil as low as 0.1mg/kg can reduce the life of small and medium-sized shrimp by 20%, and the oil content in water more than 10mg/kg will cause the death of Marine organisms; When the mineral oil content in fresh water reaches 10mg/kg, it will cause the fry to develop malformation and make the fish smell; When the oil content reaches 300mg/kg, it can kill freshwater fish. Even if the discharged waste liquid is treated with strict mineral oil recovery treatment, its long-term accumulation in the water can not be ignored. The environmental pollution of additives in cutting fluid is also very serious. For example, the short-chain chlorinated paraffins contained in the extreme pressure agent cutting fluid are very harmful to the aquatic environment, especially to water microorganisms, shells and fish, so these products are listed as serious Marine pollutants in the IMDG (International Maritime Dangerous Goods Code). The European Chloride Manufacturing Association has labeled such products "harmful to the environment", in Germany and northern Europe, has long banned the use of chlorine additives, in water-based cutting fluid, commonly used sodium phosphate as an anti-rust agent, research shows that the accumulation of phosphate makes rivers, lakes, and red tide. The harm of cutting fluid to human beings is mainly the pollution of drinking water. Since most of the drinking water in many countries is taken from groundwater, the discharge of cutting fluid waste can directly affect the quality of groundwater. According to the investigation of China's water resources department, the current discharge of waste sewage has more than doubled in the 1980s, the annual discharge of waste sewage reached 60 billion tons, more than 80% of these waste sewage is directly discharged into the river and lake reservoir without treatment. The pollution of urban water supply environment in China is becoming more and more serious, the pollution rate of urban water area is as high as 90%, and many urban water supply sources are threatened. Modern medicine has found that water is soon the source of life, and 80% of human diseases are related to water. Toxic substances in garbage, sewage, pesticides, petroleum and other wastes can easily enter the food chain through groundwater or surface water. When contaminated animal and plant food and drinking water enter the human body, it may cause cancer or other diseases.

02 Domestic normative policy driven picture With China's accession to the WTO, international standards have become a condition that Chinese enterprises must abide by, and ISO standard certification is a pass for enterprises to go to the international market. In September 1996, the International Organization for Standardization launched the environmental version of the ISO 9000 series in Europe -ISO 14000 certification standard, which is the core of environmental protection content. In order to cooperate with this standard, on January 4, 1998, by the State Environmental Protection Bureau, the State Economic and Trade Commission, the Ministry of Foreign Trade, the Ministry of Public Security and other four departments, in accordance with the Law of the People's Republic of China on the Prevention and Control of Environmental Pollution by Solid Waste, the National List of Hazardous Waste (Environmental Protection (1998) 089)} was formulated. It is clearly stipulated that waste soap liquid, emulsified oil/water, hydrocarbon/water mixture, emulsion (paste) cutting agent, coolant, lubricant, wire drawing agent, etc. are hazardous wastes, so waste cutting liquid must be treated before discharge. Since 1973, the first release and implementation of the {GBJ4-73 industrial "three wastes" discharge implementation standards} related to sewage discharge, environmental protection administrative departments have issued a series of water environmental pollutant discharge standards, forming a relatively complete water environmental pollutant discharge standard system. Its legal effect is equivalent to that of technical regulations. Different regions and different waters in China have formulated their own sewage discharge standards. In addition, the sewage discharge standards closely related to the cutting fluid are GB 3551--1983 petroleum refining industry water pollutant discharge standards, JB 7240--1995 machinery industry oily wastewater discharge regulations. 03 Cutting fluid wastewater treatment picture When the cutting fluid is replaced during the maintenance of the workshop equipment, its main components, such as lipids, emulsified oil, surfactants, and defoamer, result in a very high petroleum value of the cutting waste liquid, which can reach tens of thousands of mg/L. At the same time, due to the lack of oxygen, the anaerobic bacteria are rapidly propagated in the waste liquid, resulting in extremely unpleasant odor, because the first phase of the sewage treatment station can not remove the above substances, such as discharging it into other oily sewage mixing treatment needs to greatly increase the investment, therefore, it is necessary to pre-treat the cutting waste liquid, so that 90% of the pollutants are removed and then discharged into the sewage treatment station and other sewage mixing treatment. Reduce the treatment load of sewage treatment station and save one-time investment. In China, high concentration and severe emulsification of oily wastewater discharged in mechanical processing has not been well treated, and the current common treatment methods for waste cutting fluid are mainly divided into the following: 1) Physical treatment: Its purpose is to separate the suspended turbidity in Fa Fu from the aqueous solution. There are three ways to do this: Sedimentation separation and floating separation using the difference of specific gravity between suspended turbidity and water. The use of Filter Material filtration separation. Membrane separation is another common treatment, including two forms of ultrafiltration and reverse osmosis. Reverse osmosis and ultrafiltration processes are similar but different: Operating pressure is different, more than filtration generally only 0.1∽1MPa low pressure, reverse osmosis requires 1∽10MPa high pressure; The range of separation particles is different: ultrafiltration separation of solute relative molecular mass of about 1 million ~ 5 million, molecular size of about 5 ~ 30nm polymer, reverse osmosis can separate only a few tenths of a nanometer size of inorganic ions and organic small molecules; The removal rate of COD and BOD by ultrafiltration is low, and the removal rate of COD and BOD by reverse osmosis is greatly improved. The reverse osmosis membrane allows only water molecules to pass through under high pressure, and does not allow potassium, sodium, calcium, zinc plasma and viruses and bacteria to pass through, so it can obtain high-quality pure water. The wastewater and oil containing surfactants in cutting fluid exist as micron particles, which is difficult to separate. Ultrafiltration method does not need to break milk, through the permeable membrane to separate large molecular weight oil droplets and water, so that oil and water separation, the effluent oil content is less than 10mg/L. Ultrafiltration is ideal for removing oils, lipids and suspended solids, but cannot extract dissolved solids. Ultrafiltration method can treat about 190-56800L of wastewater per day, the process is relatively simple, the general wastewater treatment uses ultrafiltration technology, and the reverse osmosis or reverse osmosis combined with ultrafiltration technology to meet the water supply requirements.

Centrifugal separation by centrifugal device.

2) Chemical treatment: It is a fine suspended particle or colloidal particle that has not been separated in physics (particle intuition is 0.01~10? There are four ways to treat or chemically treat the harmful components in the waste liquid to make them harmless: The use of inorganic coagulants (Polyaluminum Chloride, aluminum sulfate soil, etc.), or organic coagulants (polyacrylamide) to promote the agglomeration of substances such as fine particles and colloidal particles. The use of oxygen, ozone and other oxidants or electrolysis REDOX reaction to treat harmful components in waste liquid REDOX method. The use of active solids such as activated carbon to adsorb the harmful components in the waste liquid on the solid surface to achieve the purpose of adsorption, but the lack of economic. Activated coal is a small particle produced by the factory that does not meet certain specifications (also known as the sieve residue) not only has the properties and effects of activated carbon, but also has a larger surface area, which can adsorb more substances in sewage, and the economy is better.

The use of ion exchange resin to make the harmful components of the ion system in the waste liquid ion exchange method to achieve the purpose of treatment.

3) Biological treatment: The purpose of biological treatment is to treat the organic matter (such as organic amine, non-ionic active agent, polyol, etc.) in the waste liquid which is difficult to be removed by physical and chemical treatment. The representative methods are bacterial sludge method and dispersive filter bed method. Bacteria-added sludge method is to mix bacteria-added sludge (microbial proliferator) with waste liquid for ventilation, and use microbial decomposition to deal with harmful substances (organic matter) in waste liquid. The dispersive filter bed method is to use microorganisms to decompose organic matter in the waste liquid when it flows through the surface of the filter material filling bed (filter bed) covered by microorganisms. 4) Combustion treatment: There are direct burning method and the "evaporation enrichment method" which evaporates and concentrates the waste liquid and then burns it.