Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

When people wielding the ball, only by hitting the racket's "sweet zone" can they play the best player effect. Similarly, if you want to hit the "sweet zone" of the water -soluble cutting fluid and make it play a multi -function, the content of mineral oil in the formula must be just right. Only in this way can you find "subtle balance" between different characteristics and avoid taking care of it!

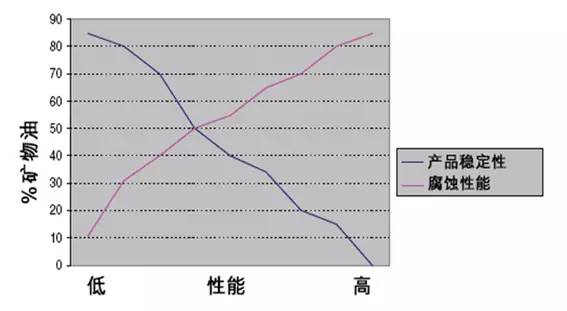

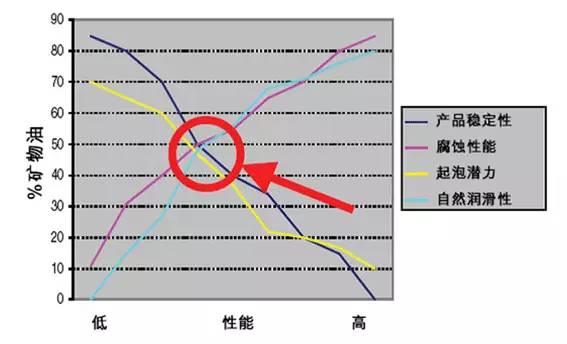

From the perspective of these two extreme situations, the effects of mineral oil content on emulsion stability and corrosion protection are completely different. The stability and corrosion protection of the water -soluble cutting fluid are the key factor affecting the processing accuracy of the equipment. To take into account these two major properties, the balance of the two must be grasped. Although Figure 1 is a simplified test result, it can still be seen that the intersection of the two trend lines is about 50%of the oil content of mineral oil.

The lower the mineral oil content, the higher the possibility of foaming, and the long and lasting foam can affect the cutting fluid and its lubrication performance. Therefore, in order to further determine the "balance point", the relationship between the potential and the mineral oil content in the formula, and the relationship between the relationship between lubrication and the foaming to the previous schematic diagram, we will find that if the mineral oil content is 40%, if it is 40% -55%of this range can achieve the best balance between foaming and lubrication.

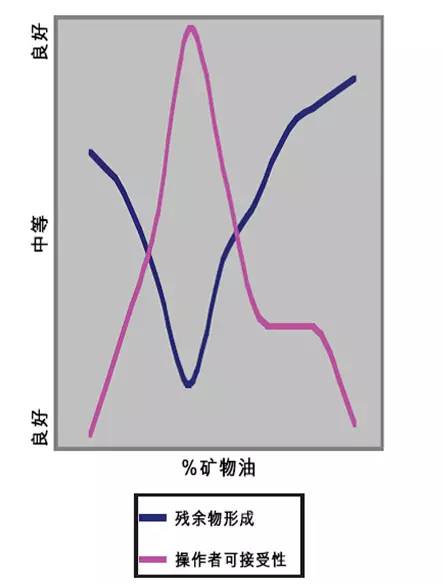

The level of mineral oil content is closely related to the harmful residues of the cutting fluid after the evaporation of the water evaporate, and the health and safety of the operator. Therefore, it is necessary to understand how much mineral oil contains can not only reduce harmful residues, but also reduce the skin irritation and health hazards of operators.

November 08, 2024

April 26, 2024

April 26, 2024

Magnesium alloy processing new favorite: Environmentally friendly nano cutting fluid, efficiency and green win-win secret? Advantages of environmentally friendly nano-cutting fluid applied on...

How to adjust a stable microemulsion cutting fluid? The deployment tutorial is here! In modern metal processing, the selection and allocation of cutting fluid is crucial to ensure processing quality...

Nanoscale cutting fluid: the new star of the market, the challenger of traditional cutting fluid In recent years, with the rapid development of science and technology and the continuous progress of...

Discussion on common problems in the use of wire cutting working fluid Wire cutting technology, as a precision machining method, plays a vital role in industrial production. However, in the process...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.