Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

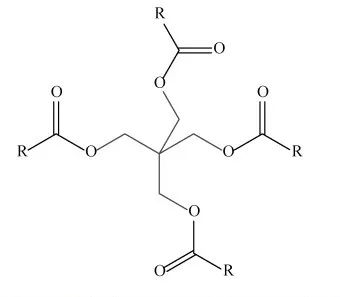

The most common polyol ester structure is neopentyl polyol ester, which is mainly obtained by esterification and dehydration of neopentyl alcohol and fatty acid. Pentaerythritol ester, trimethylolpropane ester and neopentyl glycol ester are representative of several neopentyl polyol esters.

November 08, 2024

April 26, 2024

April 26, 2024

Semi-synthetic water-based cutting fluid smelly foam rust discoloration and other 8 problems As an indispensable auxiliary material in modern metal processing, semi-synthetic water-based cutting...

Discussion on high temperature chain oil base oil, additives and formulation technology With the rapid development of modern industrial technology, the problem of equipment lubrication under extreme...

Development trend of new energy vehicles and lubricating oil base oil industry in 2024 With the increasing global awareness of environmental protection and the transformation of energy structure, the...

What is the difference between synthetic ester base oil and ordinary base oil? As a key component of refrigeration equipment and systems, the performance of refrigeration oil directly affects the...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.