Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

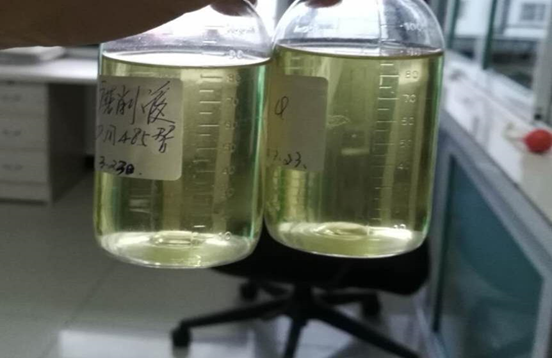

1. Water quality factor: the system contains polyether 1 but does not contain polyether. The customer himself uses local tap water. It is recommended that the customer use purified water and end customer deep well water to mix them. After they are adjusted, they should stand still to see if there is any change. It is proved that precipitation is not related to polyether 1.

2. When 5% polyether 1740 is added, the other ingredients remain unchanged, and the content of polyether 1 in the antirust agent remains unchanged. Add the same amount of polyether 2 and polyether 3 to distinguish them, depending on the actual effect.

November 08, 2024

April 26, 2024

April 26, 2024

Semi-synthetic water-based cutting fluid smelly foam rust discoloration and other 8 problems As an indispensable auxiliary material in modern metal processing, semi-synthetic water-based cutting...

Performance evaluation and application strategy of anti-rust oil: the way to ensure long-term stability of metal parts In the broad field of metal processing and storage, anti-rust oil is a key...

Anti-rust agent disclosure: The dual challenge of anti-rust and anti-emulsification properties In the world of metal processing and lubricating oil, the existence of rust inhibitors is like a patron...

Preparation method of anti-rust emulsion oil for ultra-fine copper wire drawing and strategy for improving anti-rust and cleaning performance I. Introduction When high-speed wire drawing, the...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.