Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

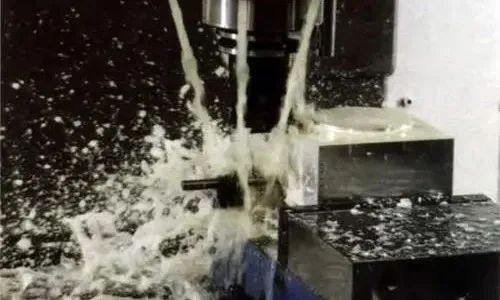

Corruption of the cutting fluid will affect the equipment, working environment and personal health, and may also affect the life of the new fluid. The necessary scientific management of water-soluble cutting fluids seems a little troublesome on the surface, but due to proper management and prolonging the service life, it will save man-hours, costs and pollution to the environment.

The deterioration of water-soluble cutting fluid is the result of the rapid reproduction of microorganisms under suitable conditions, resulting in biochemical changes in the cutting fluid. Microorganisms that cause spoilage are fungi, actinomycetes, bacteria and yeast. The bacteria are numerous and widely distributed, and can be found in the atmosphere, soil, rivers, and natural objects. The following representative fouling bacteria are often found in corrupt cutting fluids:

A slight rancid smell is produced, "Monday phenomenon"; The working fluid becomes gray-brown or red; PH value and rust resistance drop suddenly and sharply; ; Decrease in processing performance; Produce odor and pollute the environment.

November 08, 2024

April 26, 2024

April 26, 2024

Magnesium alloy processing new favorite: Environmentally friendly nano cutting fluid, efficiency and green win-win secret? Advantages of environmentally friendly nano-cutting fluid applied on...

How to adjust a stable microemulsion cutting fluid? The deployment tutorial is here! In modern metal processing, the selection and allocation of cutting fluid is crucial to ensure processing quality...

Nanoscale cutting fluid: the new star of the market, the challenger of traditional cutting fluid In recent years, with the rapid development of science and technology and the continuous progress of...

Discussion on the problem of difficult cleaning of drawing oil for cold rolled sheet In the process of cold-rolled sheet processing, stamping and drawing is an important link, and the use of drawing...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.