Cutting oils can also affect CpK!

July 31, 2022

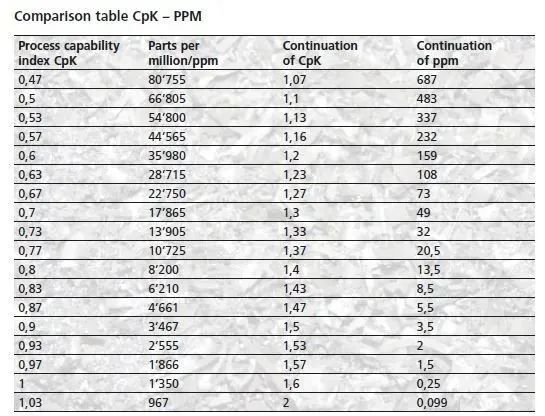

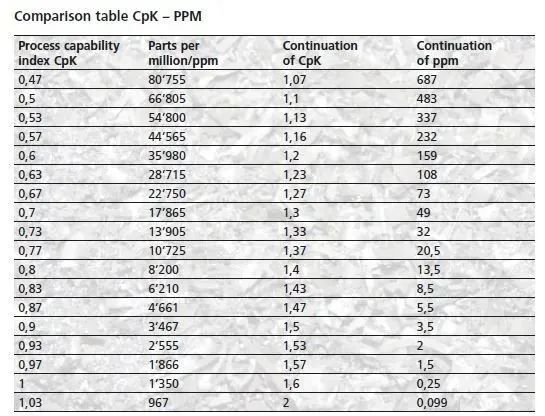

Influence of Cutting Oil on Engineering Capability Do you know? The performance parameters of cutting oils can be precisely measured, so they constitute an important factor in the assurance of process capability? CAQ (Computer Aided Quality Assurance) is now a regular feature of the bar turning business, along with cutting edges made of future materials, high-performance cutting oils and state-of-the-art machine tools. The CAQ system (Computer Aided Quality Assurance System) analyzes, records and archives quality data related to the production process. The analysis, recording and archiving of this important data is very important for businesses. The analysis, recording and archiving of this important data is very important to companies as they strive to minimise the risks associated with product liability legislation. For example, a market like the United States requires a seamless system that can be verified over many years to ensure relevant data in all key areas such as GMP (Good Manufacturing Practice in Medical Technology) and GDP (Good Documentation Practice). Process Capability Index CpK The CpK value (Process Capability Index) is an indicator used to evaluate process performance capability. It indicates how often (according to the specification document) the defined goal is achieved. CpK is defined as an average value. The higher this index is set, the more the entire production process conforms to the specification.

Example: If the CpK value is 1.07, it means that 687 parts per million (ppm) are out of the specified tolerance. What does machine capability mean? Machine capability is a term in the field of production technology that refers to the stability and repeatability of a production step on a machine in production. This makes it possible to determine the proportion of scrap and rework material that is generated when a machine is in operation. In order to determine the capabilities of the machine under carefully defined conditions (e.g. machine at operating temperature, adequately trained operators, normal environmental conditions, defined workpieces, etc.), a random sample of workpieces was fabricated using previous statistical criteria (e.g. : 500 units), after which the key parameters for the future function of the part are measured. In addition to this, a statistical distribution is to be compiled for this random sample. For teaching purposes, a normal distribution is usually assumed, although this rarely happens in a real production environment. You will now proceed to determine the location and extent of the parameters you are measuring. Thus, machine capability can be defined as a numerical value. In modern businesses, it is common practice to use either 1.33 (corresponding to 8 sigma standard deviation of a normal distribution) or 1.67 (corresponding to 10 sigma) as the machine capability index. The smaller the value, the less capable the machine is. Cutting oil as process parameter As a process parameter, the cutting oil undertakes the important functions of cooling the workpiece and the tool, lubricating the contact point of the tool and the workpiece, and removing chips. Few operators today change process oils based solely on the description of a technical product. Only realistic testing can reveal the true performance level of a certain grade of cutting oil. In 2020, MOTOREX demonstrated the capabilities of the SWISSCUT ORTHO range of high-performance cutting oils in a factory comparison test of a leading German auto parts manufacturer, demonstrating in an objectively quantifiable and verifiable manner its beneficial Product Features. In this case, stakeholders are interested in establishing precise, quantifiable factors that have a direct impact on process capability: 1. Comparison of service life 2. Dimensional integrity 3. Surface texture Harsh Processing During the test, the same workpieces made of high-strength chromium-molybdenum steel were examined on several different machines, applying the same process parameters and tools in series production. First, these tests evaluate the results of the three process capability factors described above, as well as the performance capability of the cutting oil. As the evaluation here shows, tool life can be greatly improved by using SWISSCUT ORTHO cutting oils. This also means that high-quality cutting oils can make an important contribution to process reliability and capability. For example, if the tip breaks in the "ghost layer", this will immediately negatively affect the CpK value.

SWISSCUT ORTHO lives its beliefs through data Reduce the cost of sharpening and setting knives Deeper tool usage levels Increased availability of equipment ➞ Increased utilization Reduced scrap rate ➞ High CpK value Increase productivity by reducing the number of tool changes Increase productivity by increasing cutting speed Improve surface quality In conclusion, it can be said that SWISSCUT ORTHO has the advantage of having a direct and positive influence on all measured parameters. In particular, greatly improved tool life, improved surface quality and increased productivity have helped convince the experts concerned that these complex parameters are reflected in the CpK value.