Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

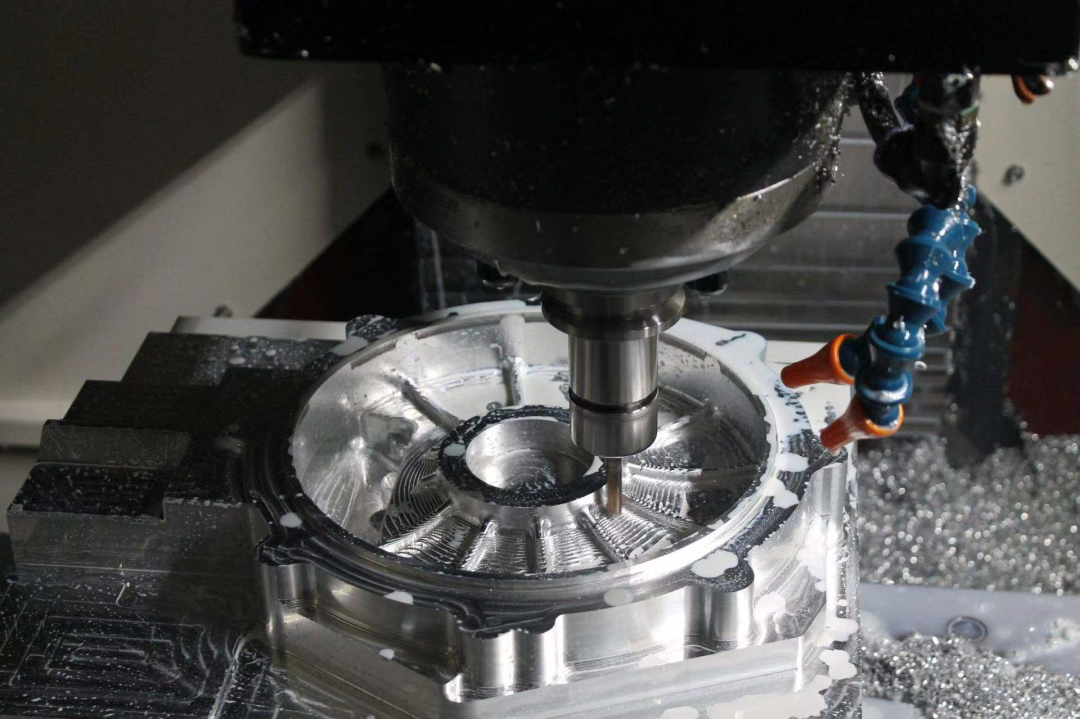

Magnesium alloy is an alloy based on magnesium and composed of other elements. Its characteristics are: low density, high strength, high elastic modulus, good heat dissipation, good shock absorption, greater ability to withstand impact loads than aluminum alloy, and good corrosion resistance to organic matter and alkali. Mainly used in industrial sectors such as aerospace, transportation equipment, chemical equipment, medical equipment, and rocket missile manufacturing. Among the practical metals, the proportion of magnesium is about 2/3 of aluminum and 1/4 of iron, so it is the most light metal among the practical metals, with high strength and rigidity. Thanks to the transformation and upgrading of China's automobile manufacturing industry and 3C product and communication component manufacturing industry, the application of magnesium alloy materials has become increasingly widespread and in-depth.

The use of water-based lubricating and cooling media for magnesium alloy processing has been allowed in the international metal processing industry since the mid-1990s, primarily due to the rapid development of material applications in the automotive industry and progress in the research and development of metal working fluids. The main principles and application issues of magnesium alloy process management can be summarized into five aspects: anti oxidation, hydrogen suppression, resistance to hard water, non odorous liquid, and safety assurance.

November 08, 2024

April 26, 2024

April 26, 2024

Magnesium alloy processing new favorite: Environmentally friendly nano cutting fluid, efficiency and green win-win secret? Advantages of environmentally friendly nano-cutting fluid applied on...

How to adjust a stable microemulsion cutting fluid? The deployment tutorial is here! In modern metal processing, the selection and allocation of cutting fluid is crucial to ensure processing quality...

Nanoscale cutting fluid: the new star of the market, the challenger of traditional cutting fluid In recent years, with the rapid development of science and technology and the continuous progress of...

Discussion on common problems in the use of wire cutting working fluid Wire cutting technology, as a precision machining method, plays a vital role in industrial production. However, in the process...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.