Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Popular science

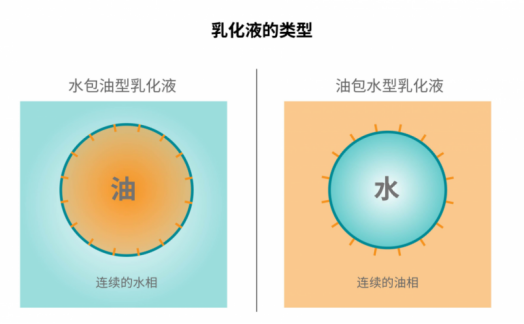

The use concentration of water-soluble metalworking fluid is usually 5%~15%. The diluent can be divided into two types, one is semi-synthetic or emulsion, and the other is fully synthetic.For metalworking fluid whose diluent is semi-synthetic or emulsion, if the concentrated solution is added to the water during the dilution process, it will form oil-in-water emulsion, which is also the ideal state for dilution. If water is added to the oil, a part of it will form oil-in-water emulsion.

November 08, 2024

April 26, 2024

April 26, 2024

During the stretching process, two relatively sliding metal surfaces, the raw material and the mold cavity, move relatively under high pressure and high speed. Due to the plastic deformation and flow...

Fully synthetic, semi-synthetic and emulsion are the three most commonly used cutting fluids. 1. Fully synthetic: water solution is the cutting fluid with water as the main component. Water has good...

Cutting fluid is a kind of working fluid used for cooling and lubricating tools and machined parts in the process of metal cutting, cutting and grinding. Cutting fluid is an important supporting...

There are many tests to evaluate the lubricity of metalworking fluids. Each experiment has its inherent advantages and limitations. The lubricity test can be broadly divided into three categories:...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.