Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

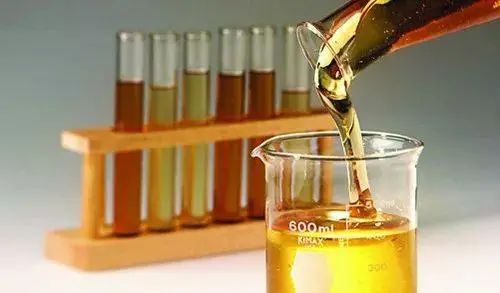

Air compressor lubricating oil undertakes the important functions of cooling, sealing and lubrication during the operation of the air compressor, and also has the functions of shock absorption, noise reduction and part of the power transmission.

In addition to the causes of discoloration described above, there is a special case where the color of the oil changes to green. After the follow-up study of many cases, it was found that when the oil turned green, the acid value was detected to increase and the increase was large. The acid value will be allowed to reach more than 2mgKOH/g, which is 10 times higher, indicating that the deterioration of the oil has been very serious.

November 08, 2024

April 26, 2024

April 26, 2024

Magnesium alloy processing new favorite: Environmentally friendly nano cutting fluid, efficiency and green win-win secret? Advantages of environmentally friendly nano-cutting fluid applied on...

Medical device grease standard mystery, what is the future trend? Grease for medical devices plays a vital role in medical equipment, and its quality and performance are directly related to the...

Nanoscale cutting fluid: the new star of the market, the challenger of traditional cutting fluid In recent years, with the rapid development of science and technology and the continuous progress of...

Discussion on the problem of difficult cleaning of drawing oil for cold rolled sheet In the process of cold-rolled sheet processing, stamping and drawing is an important link, and the use of drawing...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.