Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Micro lubrication (MQL) processing involves the application of a small amount of lubricant in the processing process in an attempt to replace the traditional flood coolant system. Understanding the correlation between fluid performance and MQL performance can help select lubricants from a variety of choices without extensive processing tests. This study compares the physical properties, wettability, tribological properties (lubricity and extreme pressure (EP) properties), fog properties and machinability of nine different MQL fluids to determine the correlation between the measured properties and MQL drilling and reaming properties. The results show that low fluid viscosity, high fog concentration, large droplet diameter and high wettability are most related to good processability. Although it is difficult to have a strong relationship, under mild cutting conditions, the best processing of low-viscosity fluids may also have the highest fog concentration, the maximum titer and the best wettability.

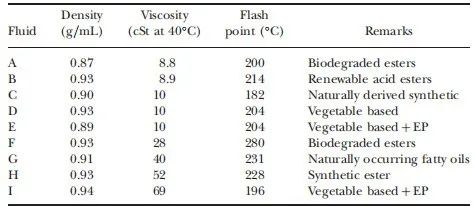

Table 1 Tested MQL lubricating oil (in order of viscosity rise)

Physical properties - thermal conductivity

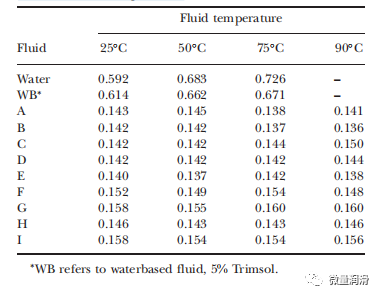

In the micro-lubrication (MQL) process, the heat generated is the same as that in the traditional process, but the fluid that can take away the heat is much less. Therefore, the thermal characteristics of the fluid can be an indicator of its heat removal capacity. In order to consider the effect of temperature on micro-lubrication (MQL) lubricants, the thermal performance analyzer KD2Pro (ThermoTest Company, Texas) was used to measure the thermal conductivity at 25, 50, 75 and 90C. A water-based liquid, Trimsol (marked as WB in all tests), was also tested at a concentration of 5% to compare it with a trace lubricant (MQL) lubricant. Each lubricant sample is measured in a thermal isolation box with temperature control to ensure the reliability of the results.Table 2 Thermal conductivity of micro-lubrication (MQL) lubricant at different fluid temperatures (W=m-K)

November 08, 2024

April 26, 2024

April 26, 2024

Magnesium alloy processing new favorite: Environmentally friendly nano cutting fluid, efficiency and green win-win secret? Advantages of environmentally friendly nano-cutting fluid applied on...

How to adjust a stable microemulsion cutting fluid? The deployment tutorial is here! In modern metal processing, the selection and allocation of cutting fluid is crucial to ensure processing quality...

Nanoscale cutting fluid: the new star of the market, the challenger of traditional cutting fluid In recent years, with the rapid development of science and technology and the continuous progress of...

Discussion on common problems in the use of wire cutting working fluid Wire cutting technology, as a precision machining method, plays a vital role in industrial production. However, in the process...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.