How to select hydraulic oil under special requirements?

December 20, 2022

What hydraulic oil is used for hydraulic equipment in high temperature open flame occasions? Fire resistant hydraulic oil/fluid should be used in high temperature and flammable occasions.

Fire resistant hydraulic oil/fluid can be divided into the following categories: HFAE: oil in water emulsion fire-resistant hydraulic fluid (water content greater than 80%) HFAS: Water based fire-retardant hydraulic fluid (with water content greater than 80%) HFB: water in oil emulsion fire-resistant hydraulic fluid (water content less than 80%) HFC: fire-retardant hydraulic fluid containing polymer aqueous solution (water content less than 80%) HFDR: ester type fire-resistant hydraulic fluid 1. As the water content of HFAE oil in water emulsion is up to 80%, it has high specific heat, good flame resistance, excellent cooling performance, low cost, harmless to human body, and good adaptability to general non-metallic materials. However, because it is a water containing liquid, with high steam pressure and poor lubricity, the operating temperature cannot exceed 50 ℃, and the system pressure cannot exceed 7.0MPa. It is applicable to the hydrostatic hydraulic system of coal mine hydraulic support and other hydraulic systems or mechanical parts that do not require the recovery of waste liquid and do not require the use of good lubricity, but require good fire-retardant liquid. 2. HFAS water-based fire-resistant hydraulic fluid, also called high water base fluid, is usually composed of 95% water and 5% water-soluble chemicals. It is incombustible, non compressible, has high heat capacity and thermal conductivity, and has good cooling effect. The operating temperature of the system is usually lower than that of the oil system. Low viscosity, fast dirt precipitation, low price (only 1/5-1/10 of the cost of mineral oil), non-toxic, pollution-free, easy to handle. The service temperature should preferably be 4~50 ℃. If the temperature is too low, it may freeze, if the temperature is too high, it may evaporate too fast. The lubricating property of water is poor, so its operating system pressure cannot be higher than 7.0MPa. In addition, it is not suitable for aluminum, magnesium, lead, zinc, galvanized steel (material), cadmium metal materials, cork, paper, butyl rubber, leather, most paints and coatings. Pay attention when using. It is suitable for low pressure hydraulic systems and metal working machines that need fire-resistant liquids. 3. HFB water in oil emulsion is composed of 60% mineral oil and 40% water. Fine water particles are dispersed in the continuous phase of mineral oil, and water is a flame retardant component. Compared with mineral oil, the lubricating performance of water in oil emulsion is relatively low, which limits its use in high-pressure systems. Due to the water content and high steam pressure, the maximum temperature used cannot exceed 65 ℃. One of the main problems in the use of water in oil emulsion is its stability. Long standing, high temperature and pollution will cause phase separation, which accelerates the premature damage of the pump. The main advantage of water in oil is that it can use the same non-metallic materials as mineral oil, including seals, hoses and coatings. In addition to magnesium, it can adapt to general metal materials. It is suitable for medium pressure and high pressure, high temperature and flammable systems in metallurgy, coal mine and other industries. 4. HFC water glycol liquid is also a kind of fire resistant hydraulic fluid with water as the fire resistant component, which is composed of 30-55% water, 25-45% ethylene glycol, glycerin or their polymers, as well as water-soluble thickener, antiwear agent, antirust agent, Anti Foam agent, etc. The liquid has excellent flame resistance, high viscosity index, good stability and fluidity, and is a transparent real solution. However, the service temperature shall not exceed 65 ℃. Generally, it is used in systems with a pressure not higher than 10MPa. It can use the same sealing materials and hoses as mineral oil, but it is incompatible with zinc, cadmium, magnesium, silver and untreated aluminum, and leather and cork cannot be used. It can soften ordinary paint and can only be used on epoxy paint or vinyl paint. Ethylene glycol has certain toxicity and should be prevented from entering the mouth, but it is not harmful to the body. It is suitable for low and medium pressure hydraulic systems in metallurgy and coal mining industries. 5. HFDR ester type synthetic fire-resistant hydraulic fluid. This kind of fire-resistant hydraulic fluid has high self ignition point, low volatility, good flame resistance, and its lubricating performance is comparable to that of the best mineral oil. It can adapt to most metal materials. However, due to its large polarity and strong solubility, common non-metallic materials that mineral oil can adapt to, such as nitrile rubber, neoprene rubber, asbestos rubber sheet, polyvinyl chloride plastic, organic glass and vinyl paint, are not suitable, and matching materials must be carefully selected. There are mainly two ester type fire-resistant hydraulic oils, one is phosphate type, and the other is fatty acid ester type. The phosphate type has a long history, and the service temperature range is - 50~135 ℃. It is suitable for hydraulic systems operating under high temperature and pressure, such as metallurgy, thermal power generation, gas turbine oil, etc. However, because of its poor hydrolytic stability, highly toxic hydrolysates, and great harm to the environment, it has been gradually replaced by fatty acid ester type fire-resistant hydraulic oil. How to select hydraulic oil varieties according to special requirements In addition to the consideration of working pressure, temperature and service environment, there are also some more detailed factors in the selection of hydraulic oil varieties: 1. According to the pump type According to the working pressure and temperature: pressure<7.0Mpa, temperature<50 ℃, use HL; HL or HM shall be used when the pressure is 7.0~14.0Mpa and the temperature is 50~70 ℃; HM is used for pressure>14.0Mpa and temperature>70 ℃. According to pump type: high zinc content of HM is recommended for vane pump (Zn in oil > 0.05%); The plunger pump uses ashless anti-wear hydraulic oil, and HL type hydraulic oil can be used for general pressure; Both plunger pump and vane pump use HM low zinc (Zn in oil < 0.03%); HL or HM is used for gear pump or screw pump. 2. According to special parts Special anti silver hydraulic oil shall be selected for the parts containing silver plating in the hydraulic system; Although HR hydraulic oil with high viscosity index should be selected for indoor operation of CNC machine tool oil; Some hydraulic systems have high-precision servo valves to choose clean hydraulic oil; The feed system of the machine tool requires that the oil has good viscosity and smoothness, and HG hydraulic guide oil is selected. 3. Hydraulic transmission system PTF-1, also known as Automatic Transmission Fluid (ATF), is used for automatic transmission systems of cars and light trucks; PTF-2 is used for the transmission system of heavy-duty trucks and off-road vehicles; PTF-3 is also known as hydraulic and transmission dual purpose or hydraulic, transmission and brake triple purpose oil. It is used in the hydraulic transmission system of agricultural and construction field machinery. 4. Environmental protection factors Biodegradable lubricating oils include: HETG belongs to vegetable oil type; HEPG is based on polyether; HEES is based on synthetic ester; HEPR is poly α- Olefin synthetic oil. Relationship between hydraulic oil cleanliness and allowable particle number Excessive particles in the hydraulic oil will block the oil filter, scratch the seals, block or wear the components. However, it is impossible for hydraulic oil to be completely free of particles during production and use. At present, domestic lubricating oil manufacturers still control the particles of hydraulic oil with "mechanical impurities"<0.005%, while foreign countries often use NAS 1638 (see Table 1) of NAS and ISO 4406-1987 (see Table 2) of the International Organization for Standardization (ISO) for constant oil cleanliness levels.

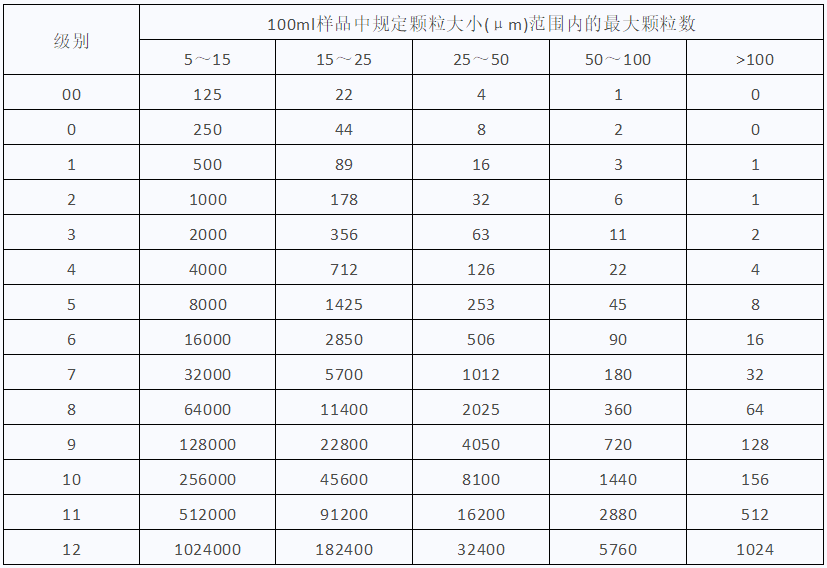

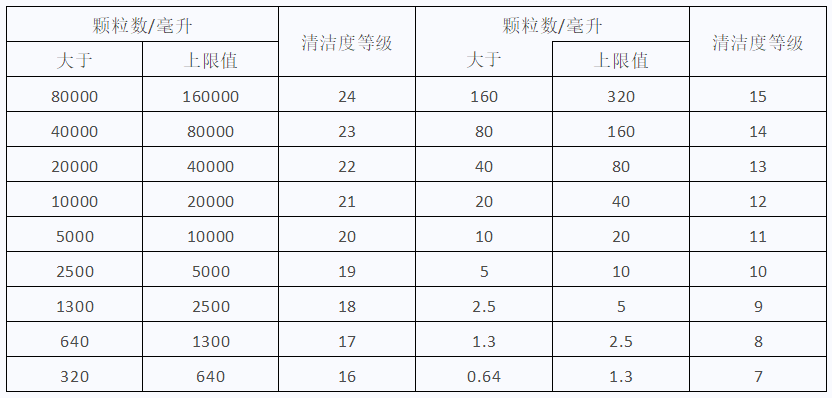

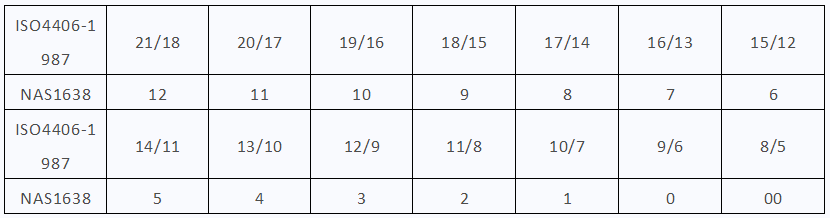

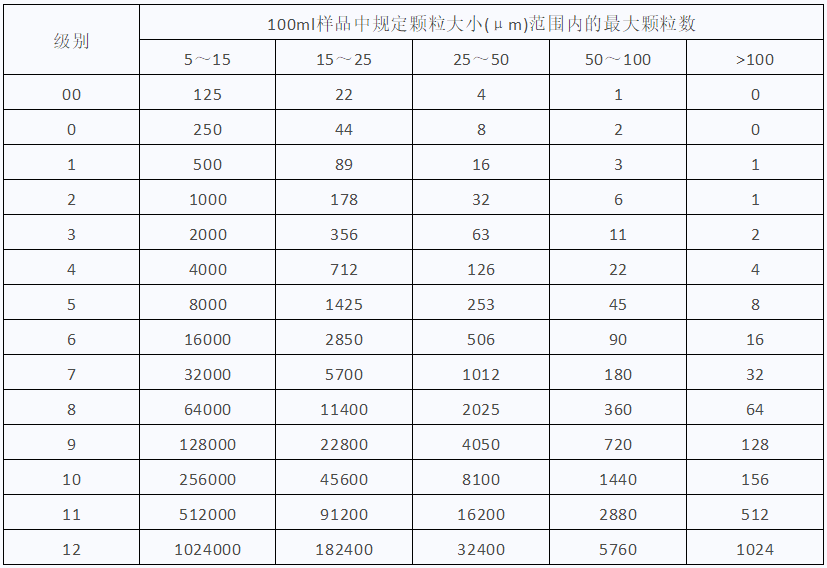

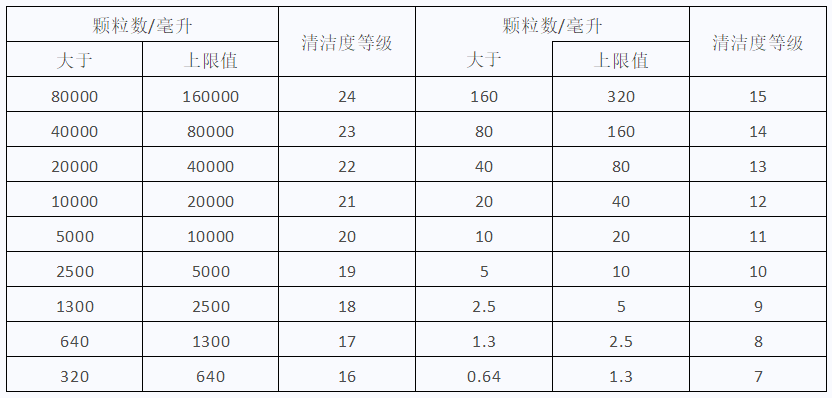

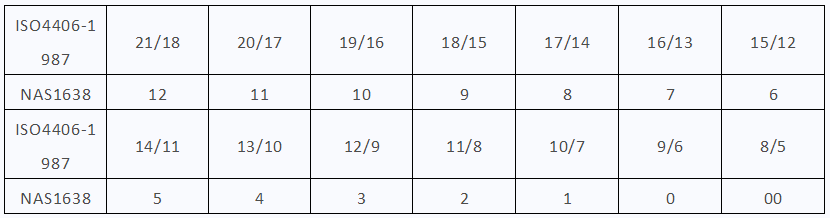

For example, the requirements for oil cleanliness of hydraulic system are as follows: ⑴ Large clearance, low pressure hydraulic system: NAS 10~12 (approximately equivalent to ISO 19/16~21/18, allowable ≥ 5 μ Number of particles/ml: about 5000~20,000; ≥15 μ: About 640-2500) (2) Medium and high pressure hydraulic system: NAS 7~9 (approximately equivalent to ISO 16/13~18/15, allowable ≥ 5 μ Particle number/ml: about 640-2500; ≥15 μ: About 80-320) (3) Sensitive and servo high-pressure hydraulic system: NAS 4~6 (approximately equivalent to ISO 13/10~15/12, ≥ 5 allowed μ Number of particles/ml: about 80-320; ≥15 μ: About 10~40) See Table 3 for the corresponding relationship between ISO 4406-1987 and NAS 1638 oil cleanliness grades. Table 1 - NAS 1638 Oil Cleanliness Grade Standard

Table 2 - ISO 4406-1987 Oil Cleanliness Grade Standard

Table 3 Correspondence between ISO 4406-1987 and NAS 1638 Oil Cleanliness Grades

What are the requirements of the development of hydraulic technology on the performance of hydraulic oil With the rapid development of hydraulic technology, the specifications of hydraulic oil are constantly revised, mainly in the following three aspects: First, the pressure of the hydraulic system has increased from 7Mpa to 14Mpa, even up to 40Mpa. With the increase of system pressure and power, the load of the oil pump will become heavier and heavier, so the oil products are required to have excellent wear resistance. Secondly, the high pressure, high speed and miniaturization of the hydraulic device increase the number of oil circulation in the hydraulic system, shorten the oil stay time in the oil tank, and increase the oil temperature from 55 ℃ to 80 ℃. Some modern large-scale hydraulic excavator hydraulic systems allow the maximum working oil temperature of hydraulic oil to be about 90 ℃, so it is required that the oil products have better thermal oxidation stability; At the same time, the increase of oil temperature makes the dissolved air in the oil increase, so the oil must have good air release property. Frequent circulation makes the disappearance of foam and the separation of water more and more difficult. Therefore, the oil should also have good defoaming property and hydrolysis stability. Third, electro-hydraulic servo valves and proportional solenoid valves are introduced into the hydraulic system. These components have high sensitivity, complex structure, small fitting clearance and high precision. Therefore, hydraulic oil is required to have high cleanliness and good filtering performance.