Micro lubrication, high pressure cooling and steam cooling, which of these new cutting fluid technologies is better

November 29, 2022

1. Aerosol and micro lubrication Minimal Quantity Lubrication (MQL) is a metal processing lubrication method, namely semi dry cutting, which refers to a cutting method that mixes and vaporizes compressed gas (air, nitrogen, carbon dioxide, etc.) with a very small amount of lubricating oil to form droplets of micrometer level and spray them to the processing area for effective Lubrication (see Figure 1-56). Figure 1-56 Aerosol and Microlube System

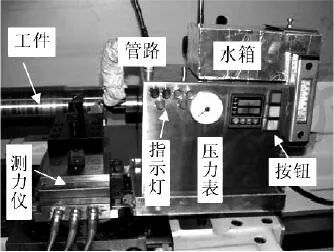

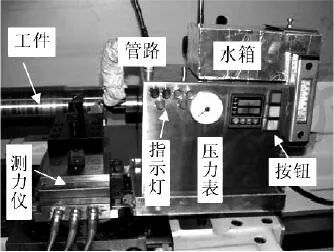

Micro lubrication MQL technology combines the advantages of dry cutting and traditional wet cutting. On the one hand, MQL reduces the amount of cutting fluid to a very small amount, which not only significantly reduces the cost of using the cutting fluid, but also minimizes the harm of the cutting fluid to the environment and human body by using synthetic esters with high natural degradation as the lubricating agent; On the other hand, compared with dry cutting, MQL has introduced cooling and lubricating media, which greatly improves the cooling and lubricating conditions during the cutting process, and significantly reduces the wear between tools, workpieces and chips, which helps to reduce the cutting force, cutting temperature and tool wear. This cutting technology, also known as semi dry cutting, has a great prospect under the influence of the theme of green environmental protection in the 21st century. In order to minimize the impact on the environment and human body, the traditional cutting fluid containing a large number of toxic additives can no longer be used as the cutting fluid for MQL cutting. The Base Oil of its green lubricant is mainly vegetable cutting oil, such as Rienberg's vegetable oil-based cutting oil. Micro lubricating oil requires high biodegradability and no harm to human body. It requires that the lubricant has good permeability and surface adhesion coefficient, super lubricity, and excellent extreme pressure performance. In addition, the size and aggregation of oil droplets in the lubricating oil mist have an impact on the lubrication effect of the tool and workpiece contact surface in the machining area. The influencing factors of oil drop size generally include the pressure of compressed air, the amount of lubricating oil and the distance between nozzles. At the same pressure, with the increase of the amount of lubricating oil and the distance between nozzles, the oil droplets become larger and the speed decreases. When the amount of lubricating oil is equal, with the increase of air pressure, the liquid drops become smaller and the speed increases. Therefore, the speed of oil droplets with large particles is low, and their gravity is more likely to deviate during transmission, leading to insufficient oil supply in the processing area, which affects the lubrication effect. Generally, the particle size of oil drops is controlled at 2 μ M below. The aggregation degree of oil droplets mainly depends on the amount and nature of lubricating oil, the amount of compressed air, and the structure of the nozzle. 2. High pressure cooling technology The so-called high pressure cooling technology (HPC) means that after the cutting fluid pressure is raised to a specific pressure, it is accurately sprayed to the required cooling area through the internal cutting fluid channel through the nozzle, so as to achieve rapid cooling (see Figure 1-57). Fig. 1-57 High pressure cooling

The initial purpose of high-pressure cooling technology is to deal with the processing of difficult to machine materials, such as titanium alloy, Inconel and other heat-resistant alloys. In practice, it is found that the tool life, productivity and chip control have been greatly improved when using high-pressure cooling technology to process stainless steel and alloy steel. (1) From the perspective of cooling effect, high-pressure cooling technology is to use high-pressure cutting fluid to spray directly to the cutting area (heat affected zone) between the front tool face of the blade and the chip in a precise and sufficient amount, so as to maximize the heat in the cutting area, so that the coolant can give play to its best performance, and achieve the goal of rapid cooling. (2) From the chip control point of view, after the high-pressure cooling processing mode is adopted, in addition to effectively reducing the cutting heat in the cutting area, it also makes the chip brittle and easy to break, so as to obtain short and small chips, which makes the chips no longer entangle around the workpiece, and the processing process does not need to stop frequently due to manual removal of long entangled chips. The distribution of cutting fluid pressure and the size of the nozzle will have a great impact on the chip. By adjusting the jet parameters, different chip curling effects can be obtained, and it is possible to guide the ribbon chips in the desired direction, or even improve the chip length. At the same time, due to the formation of a high-pressure water wedge in the cutting area, it is possible to forcibly break the chip, thereby reducing the impact of the chip on the machining effect. (3) From the perspective of tool life, after high-pressure cooling, the distance between the cutting fluid jet and the cutting edge of the blade is closer, the cutting fluid can accurately reach the cutting area between the front tool face of the blade and the chip, achieving better chip control and more effective cooling of the cutting edge, thus reducing tool wear and extending tool life. In general, accelerating the cutting speed will lead to a sharp reduction in tool life, but the reduction in tool life is not so obvious when the feed rate is increased after high-pressure cooling. The experiment shows that the cutting speed of the tool can be increased by 20%~50% compared with that of the tool supplied with conventional cutting fluid for rough machining of difficult to machine materials. 3. Steam cooling The cutting method of using water vapor as cooling lubricant was first proposed by Podgorf of the former Soviet Union in the late 1980s, that is, heating water above the boiling point in a closed container to make it have a certain pressure, and then spraying it to the cutting area at a certain initial speed through the nozzle for cooling and lubrication (see Figure 1-58). Its principle is that the cooling and lubricating medium must enter the workpiece tool chip contact area to play its role, so it is required that the cooling and lubricating medium has good penetration and diffusion capacity. The superheated water vapor particles have smaller diameter, less viscous resistance than traditional liquid cutting fluid, and it is easier to penetrate into the cutting area; The higher the water vapor temperature is, the stronger the molecular thermal movement is, and the stronger the diffusion ability is, which is more conducive to the penetration of cooling and lubricating media. On the other hand, although the heat capacity ratio of superheated steam is lower than that of liquid cutting fluid, the superheated steam, due to its certain pressure and speed, belongs to the forced heat exchange mode. The amount of superheated steam entering the cutting area in a unit time is greater than that of liquid cutting fluid, which can make up for the low heat capacity ratio of superheated steam to a certain extent.

Fig. 1-58 Water vapor cooling system