Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Cooling: The air compressor generates a large amount of heat during operation, and the oil plays a role in heat dissipation.

Lubrication: Oil forms a protective film on the metal surface to reduce wear. The oil film of No. 46 is thicker than that of No. 32, especially during cold start, which can better protect the metal surface.

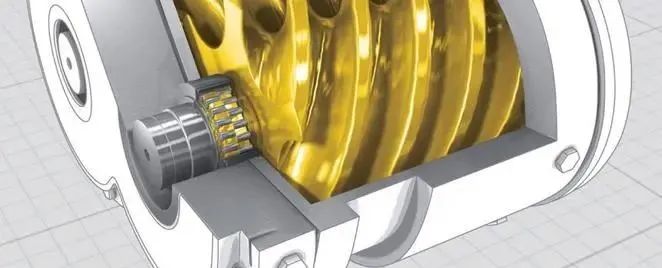

Sealing: The lubricating oil in the compression chamber of the screw host can reduce leakage.

Sound reduction: reduces the noise of the host during operation.In the after-sales market, it is necessary to understand the oil usage history of air compressors. If there have been problems with previous oil products or if they are not using legitimate brands of oil, please handle them properly. Because low-quality oil oxides will remain in the machine, seriously affecting the service life of new oil.

Frequent problems with air compressor oil

Coking

The base oil of air compressor oil is not good, and there are many impurities such as gray matter inside. These substances are easily oxidized, and through high-temperature and air oxidation reactions, they form tar like sludge. In severe cases, it can cause the head of the air compressor to lock up, and the common precursor of gluing is that the compressed air becomes odorous and the operating current of the air compressor is high.

Carbon deposition

Under high temperature operation of the air compressor, especially when the temperature exceeds 95 degrees, the light and heavy components of the oil will separate, and after oxidation, they will adsorb on the surface of the components like paint, causing blockage of the oil separator, wear and oil leakage of the machine head oil seal, and shortening the service life of the bearings.

Oil emulsification

The air compressor operates at low temperatures for a long time, and the water in the machine cannot evaporate in a timely manner. The mixture of oil and water emulsifies like a milk like liquid.

High oil content at the air outlet

The oil has poor oil gas separation, and the base oil contains a lot of hydrides, making it difficult to separate from compressed air.

Abnormal color of old oil

Usually, the color of the oil product will turn dark red or black, but if it turns purple or other colors, it indicates the use of oil additives improperly, it is recommended to replace the oil in a timely manner.

Problem prevention and control measures

1. It is necessary to use oil according to the regulations of the compressor equipment and shorten the usage time of the oil appropriately.

Before each oil change, the oil circuit of the compressor should be cleaned to prevent debris and coking substances from blocking the oil circuit. If coking is found (even if it is rare), it is necessary to undergo professional cleaning. After cleaning, the air filter, oil filter, and oil separator should be replaced in a timely manner. According to the coking situation and economic efficiency, carbon cleaning agents, acetone cleaning, Tena water, caustic soda, etc. can be selected for cleaning.

2. Ensure the quality of compressor accessories and spare parts.

Especially, it is necessary to strictly control procurement and ensure the use of genuine compressor accessories. For example, for air filters, emphasis should be placed on the waterproofing, filtration accuracy, and breathability of the product.

3. Keep the cooling system unobstructed and ensure the supply of cooling water.

Every six months or one year, each cooler must be opened for inspection, and scale must be cleaned and maintained. For air-cooled equipment, it is necessary to clean it regularly to ensure the unobstructed cooling windows. Especially in the northern regions, many cooling water has a hard water quality, which can easily form scale and affect cooling efficiency. Therefore, special attention should be paid to descaling maintenance or cooling water softening treatment.

4. Adhere to the use of specialized lubricants.

Do not use hydraulic oil, Gear Oil, base oil or other compressor oil to replace screw compressor oil. In terms of oil function, hydraulic oil has good hydraulic transmission and wear resistance, but poor resistance to high-temperature oxidation; Gear oil has good shearing property, but high viscosity and poor high-temperature resistance; Base oil is based on additives to help achieve the functionality of the oil, and cannot be directly used without the addition of additives.

November 08, 2024

April 26, 2024

April 26, 2024

In cold temperatures, which factors should be considered when selecting air compressor oil? Main body Winter management of air compressor lubricating oil is very important, because the low...

What are the metal processing oils involved in wind power gear machining? As an important clean energy, wind energy will assume the major responsibility of the main force of new energy, it can be...

In the pipeline system of automobile exhaust pipes, the elbow is the weakest part, and its forming quality directly affects the performance of the entire pipeline. The plastic bending forming of...

The quality of degreasing mainly depends on four factors: degreasing temperature, degreasing time, mechanical action, and degreasing additive. 1. Degreasing temperature Generally speaking, the higher...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.