Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

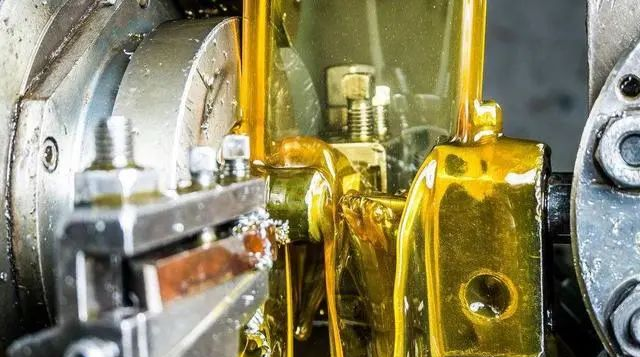

Cutting fluids are widely used in cutting processes due to their functions such as cooling, lubrication, cleaning, and rust prevention. The cutting fluid often has problems such as deterioration, odor, corrosion, foam generation, workpiece rusting, etc. In combination with the experience of metalworking fluid and additive development research and field application, the problems and countermeasures in the use of cutting fluid are discussed below.

Self emulsifying ester is a multifunctional functional group self emulsifying water-soluble ester that has three basic functions in the same product: lubrication, emulsification, and hard water stability. This product is particularly suitable for both fully synthetic and semi synthetic cutting fluids, with excellent interface lubrication, rust prevention, and cleaning effects. It effectively reduces tool adhesion, improves product smoothness, reduces tool wear, and has strong resistance to hard water.

4. Reasons for many foam when using cutting fluid

Cutting fluid components contain many surfactants, commonly known as cleaning agents. These cleaning agents will produce a lot of foam when used, which is adverse to machining. It can pollute the processing environment and cause inconvenience to production personnel. Leakage from the machine tool can also reduce the cleaning ability of the cutting fluid. At this point, a small amount of defoamer can be added (silicone oil has the fastest effect, polyether has strong persistence, and can suppress foam) to remedy the situation.

5. Odor problem during the use of cutting fluid

Cutting fluid can be divided into emulsified oil (emulsion), semi synthetic (micro lotion) and fully synthetic. Due to the large amount of mineral oil contained in emulsified oil, it provides a breeding ground for bacteria, fungi, and molds. If no fungicides are added, a large number of bacteria will grow in a short period of time, causing odor. Choosing suitable fungicides can effectively solve the problem.

November 08, 2024

April 26, 2024

April 26, 2024

In order to adapt to different processing requirements, there are many kinds of cutting fluids, which can be divided into water-based cutting fluids and oil-based cutting fluids according to chemical...

Factory workers often report that the workpiece corrosion and tool corrosion are caused by the use of cutting fluid? In fact, it is not entirely due to cutting fluid. There are many reasons for...

The cutting fluid interface lubricant is usually ineffective when the temperature is extremely low. At this time, there should be a lubricant that will not affect the lubrication in the high...

Magnesium alloy processing new favorite: Environmentally friendly nano cutting fluid, efficiency and green win-win secret? Advantages of environmentally friendly nano-cutting fluid applied on...

Email to this supplier

November 08, 2024

April 26, 2024

April 26, 2024

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+86 13783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.